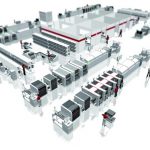

New placement modules, tapeless feeders, new screen printers and the first expert system that optimizes SMT processes automatically. At Productronica 2015 (November 10–13, Munich Trade Fair Center), technology leader ASM Assembly Systems will present a show unlike any other under the motto “On the move to the Smart #1 SMT Factory”. On 650 square meters at booth A3-377, the SMT experts will lay out their roadmap to the Smart Factory with a “Speed Quality” line and a “Flexible Quality” line featuring totally innovative technologies.

The focus will be best-in-class equipment, automation tools, production process networking and integration, and transparent material logistics. At the “Speed Quality” line, new Siplace TX placement modules will ring in the mass placement of super-small 0201 (metric) components. A single Siplace TX module alone can place up to 78,000 of these per hour at full speed at smallest footprint. With its compact design, it also sets new records in speed, floorspace performance and placement accuracy. Components in sizes from 0402 through 01005 will be supplied loosely and without tapes thanks to the new Siplace BulkFeeder. This ASM innovation finally bans reels and splicing from the SMT production floor. With the DEK NeoHorizon and DEK NeoHorizon Back-to-Back, the ASM team will also unveil new, powerful screen printers. Most of the visitors’ attention, however, will be focused on the ASM ProcessExpert. This first inline expert system in the industry establishes a new product category in electronics manufacturing. By running virtual prints based on Gerber data, the ASM ProcessExpert subjects the stencil to a DFM (design for manufacturability) health check. By stabilizing and optimizing the printing process automatically, this highly innovative system represents a milestone on the path to self-optimizing SMT lines. Each of these innovations constitutes a building block for the Smart Factory.

At this year’s Productronica, ASM will present its innovations with live demonstrations on two SMT lines: the “Speed Quality” Line and the “Flexible Quality” Line. The new Siplace TX placement modules of the “Speed Quality” Line impress with speeds of up to 78,000 components per hour while taking up only 2.3 square meters of floorspace. This jump in performance was made possible by further improvements of the Siplace CP20P SpeedStar head. The compact modules with one or two gantries allow users to configure their lines in an even more demand-oriented manner while setting new records in speed and floorspace performance.

World premiere: Siplace TX places 0201 (metric) components at full speed

With a rating of 25 µm @ 3 sigma, the Siplace TX is so accurate that even super-small 0201 components can for the first time be placed at full speed, making it future-proof. And to be able to supply the fast dual-track Siplace TX modules with enough PCBs, the “Speed Quality” Line features another innovation at this year’s Productronica: the dual-track DEK NeoHorizon Back-to-Back printer solution.

Sensational: Component feeding with no tapes and no splicing

For high-volume manufacturing, ASM has developed a new feeder technology. The new Siplace BulkFeeder X is the first feeder that can supply standard components in sizes 0402 through 01005 without tapes. Using a vibrating mechanism, the feeder pours loose components from a container onto a pickup plate made of glass. The precise interplay between shutter and vibration mechanisms, vision system, image analysis and high-precision heat control makes it possible to pick only those components off the plate that are correctly aligned, and do so with no compromise in speed. The BulkFeeder is mounted on the machine like any other feeder. Its interchangeable cartridges hold up to 1 million components. This unique feeder technology makes reels and their time-consuming, error-prone handling and splicing a thing of the past. It makes the operating staff’s work easier and simplifies the storage and transportation of components considerably.

Factory solutions support high-mix electronics manufacturing

The “Flexible Quality” Line, on the other hand, demonstrates ASM solutions for high-mix production with the successful Siplace SX placement platforms, whose performance can be quickly adapted to changing requirements by adding or removing gantries.

The SMT experts show how it’s done with various ASM factory solutions that integrate processes and provide operators and departments with transparent process control using special user interfaces – from planning to NPI and setup processes to full-speed production runs. Using these solutions, schedulers running SiCluster MultiLine can quickly integrate new production jobs and optimize their setups and sequences across lines in minutes. The usual requirements and restrictions (delivery deadlines, line performance, feeders, two-sided or modular products, maintenance intervals, etc.) are taken into account automatically. Rush jobs can be easily inserted by re-optimizing one or more lines.

Siplace Material Manager is the comprehensive solution for SMT-specific material management. It supports material-related processes ranging from receiving, warehousing, goods issue and return, rack system control, production planning and kitting to operations on the line. With the Material Tower, ASM offers an extremely compact, MSD-capable and fully software-integrated material storage system for up to 900 8-mm reels. The Material Tower allows the user to employ innovative and highly flexible setup concepts by storing components directly adjacent to the line.

ASM ProcessExpert: SMT lines optimize themselves

The “Flexible Quality” Line also features the ASM ProcessExpert, the world’s first inline expert system for SMT processes. The visible part of the system is the ASM ProcessLens, an innovative 5D SPI system. The ASM ProcessLens operates with exceptional precision, speed and flexibility because it generates its striped moiré patterns with an electronically controlled DLP (Digital Light Projector) chip. The measurement results are stored in databases and analyzed by the ASM ProcessEngine software in real time. But the ASM Pro-cessExpert is not satisfied with controlling the print quality via adjustable parameters – it is the first self-learning expert system that is able to stabilize and optimize printing processes completely on its own.

Instead of running expensive and time-consuming test prints, electronics manufacturers can now let the ASM ProcessExpert do the work. By accessing its knowledge databases and running only nine systematic test prints, it determines within minutes all relevant parameters such as as paste type, squeegee pressure, speed, cleaning cycles, etc. The ASM ProcessExpert transmits the settings to the linked DEK units before starting and controlling the printing process. If the system detects potential improvements for the ongoing production run, they will be made. For example, it the print quality permits it, it extends the cleaning intervals to make the entire process more efficient.

Another highly innovative function of the ASM ProcessExpert is the DFM HealthCheck (DFM = design for manufacturability), a virtual test print for new product introductions. After reading in the Gerber data of a stencil, the system checks each detail and determines more than the printing parameters. Using color-coded markings, it indicates which areas may result in an unstable printing process. This provides manufacturers and customers with important information about their board’s manufacturability as well as with recommendations for fixing these problems before the first board actually enters the line.

New energy for many innovations

“The merger of DEK and Siplace that formed the SMT Solutions segment of ASM Assembly Systems has led to many new ideas and synergies. At the 2015 Productronica we will present a comprehensive portfolio with many truly trailblazing innovations,” says Gabriela Reckewerth, Director Global Marketing at ASM Assembly Systems. “These new solutions deliver more speed, efficiency, flexibility and quality in electronics manufacturing. They enable us to raise our customers’ production facilities to an entirely new level and move them even closer to the Smart #1 SMT Factory.”

For more information about the Productronica program and the accompanying in-house events at Siplace headquarters in Munich as well as about individual products or to set up appointments with SMT Solutions representatives, go to www.asm-smt-solutions.com/de/productronica2015

Share: