Flexible SMT production has reached new dimensions. Pick-and-place machines have now expanded their applications to complex include dispensing tasks. Such combined placement/dispensing machines can produce products at lower costs than individual specific machines. Today, the application range is much wider because modern SMD placement machines also can be combined with high-tech metering systems.

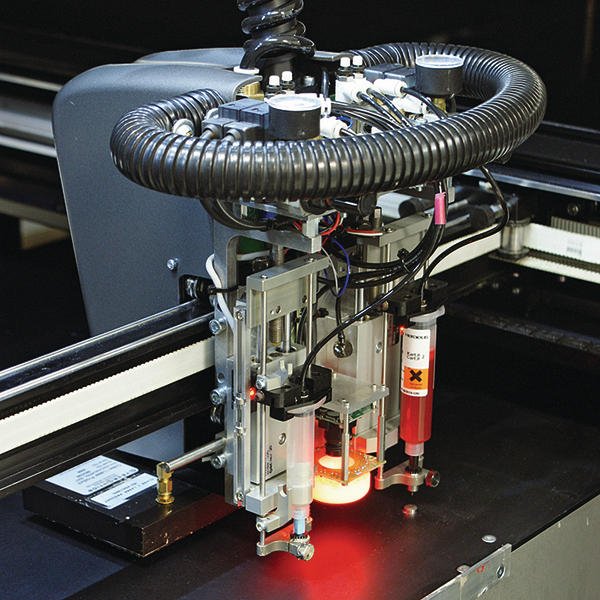

The list of dispensing valves adaptable to placement machines is long. Simple time/pressure valves can be combined with highly accurate, touchless jet valves, needle valves, screw valves, slider valves and more. Furthermore, there are heating and cooling options, spray valves, different dispensing needles and special valve versions. Jet dispensing and piezo flow valves (PFV) are the most accurate solutions. The jet valve can shoot drops with a volume of only two nanoliters, a PFV can create solder dots with only 100 µm in diameter. If large volumes are required, for example for casting or for dispensing of LED lenses, screw, time/pressure or jet valves can be good solutions.

However, the selection should not be made without the help of an experienced specialist because the number of decision factors is high: The media to be dispensed, the required volumes, the final product and the surrounding conditions. An important principle to consider is that dispensing and placement processes are always serial on combined machines. On one hand this increases the utilization of a machine, but on the other hand it limits the total production. Therefore, such solutions are less suited for high-volume production, but they are ideal for pilot lines, process and development laboratories, schools and universities, small series production and special applications.

A limitation given by the process may be the form of the dispensing dot which is always round or oval. For SMD applications this may be limiting because soldering pads normally are rectangular and cannot be filled with solder paste to the edges. A printing process using stencils or screens can be more reliable because this process can force wetting of the complete pad.

Currently development is ongoing towards 2– and 3-D motion control of the dispensing head, which was not possible until now. The the latest pick-and-place platforms such as the Paraquda from Essemtec will allow curve dispensing just like on specified dispensing machines. Therefore, the differences between a combined machine and single machines will disappear. This will allow more complex products to be produced on a single platform such as 3-D MID. The days when a dispenser was only a prototyping accessory of a pick-and-place have passed.

Share: