Viscom is a manufacturer of modern automatic optical inspection systems (AOI) for high quality standards. With the introduction of a 3D inspection system with a high-throughput camera module, the company extends its spectrum of individually configurable and preconfigured AOIs, thus guaranteeing maximum inspection depth, extremely fast inspection speed, and complete versatility for future inspection tasks.

The 3D AOI inspection system solution spectrum is based on both the S6056 – the fast high-end system with scalable, modular 3D camera technology – and the S3088 system family. With the S6056, single or double track operation can be selected for the best results when inspecting electronic assemblies: The XM and XMplus 3D high-performance camera technology delivers the highest resolution and optimum defect feature detection reliability. Thus, even the smallest components and critical defects are detected, such as 01005 components or QFPs with lifted leads in the fine-pitch range.

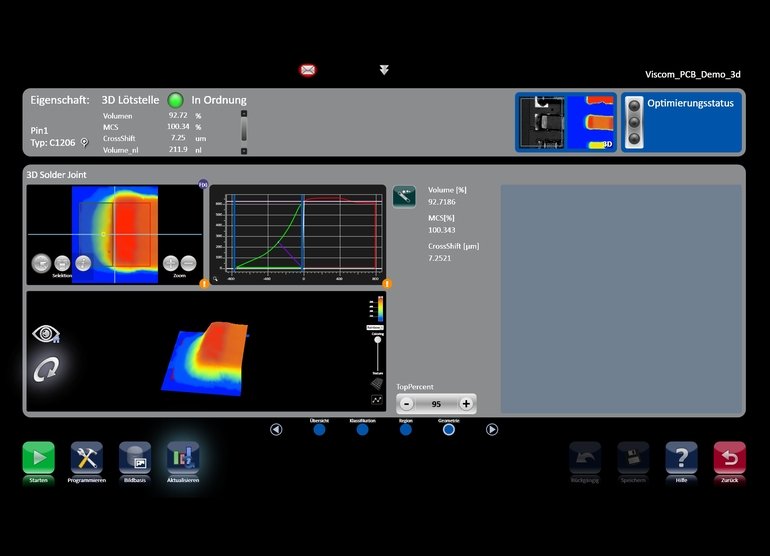

The S3088 system family includes 3D solder paste inspection, which is the first inspection stage before AOI and x-ray inspection. Even paste for the most demanding assemblies with CSPs or micro BGAs and prints for pad sizes of 01005 chips are inspected with high precision and speed (up to 200 cm2/s). Another great advantage also lies in the evaluation and linking of measurement data with the paste printer, placement machine, AOI and AXI, even higher order software systems, for effective process control and quality optimization.

The 3D AOI system “ultra” features flexible configuration possibilities conceived for the highest demands and scalable for small series production with rapid product changes, up to large series production. Different camera configurations on the XM module permit flexible use with and without 3D inspection. The high-performance 3D camera technology guarantees a virtually shadow-free inspection. The deployed angled cameras enable unhindered sight over nearly the whole field of view. This means the system will reliably inspect even de-wetting on QFPs and typical defects on QFNs and DFNs, where conventional 3D systems meet their limits. The FastFlow handling is available as another configuration possibility, to implement printed circuit board change in as little as 2.5 seconds.

With the development of the XMplus camera module, the company offers the 3D AOI “ultra gold”. The data rate of up to 3.6 gigabyte per second doubles that of the XM module. It scores with an ideal balance of both high throughput and resolution and is predestined for high-end electronics manufacture. The first-class inspection depth also covers future demands of miniaturized components in compliance with IPC.

As the very latest development, a cost-sensitive 3D AOI solution has been configured with a high-speed camera module for the Asian and American markets. The “ultra chrome” has been streamlined for large series production, with the highest throughput at the same time as excellent inspection coverage.