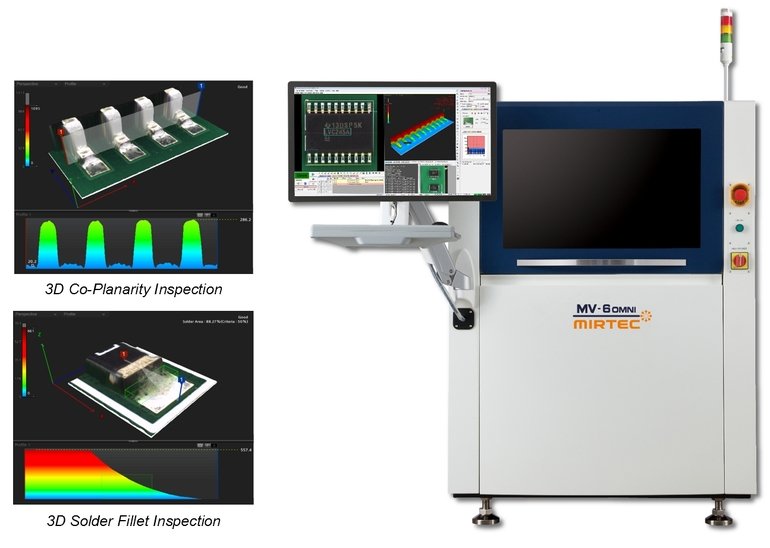

Mirtec is pleased to announce plans to exhibit its MV-6 OMNI 3D AOI system at productronica 2017, scheduled to take place at the Messe München in Germany. The company will also show the MS-11e 3D SPI, MV-3 OMNI desktop 3D AOI, and Intellisys software.

David Bennett, President of the company, commented: “We are excited to show our latest technologies, as Mirtec has again pulled away from the competition by introducing new features on the MV-6 OMNI. Another model that is already showing its leading position is the MV-3 OMNI – a 3D version of the MV-3L. The MV-3 OMNI offers the highest specification far outperforming competitive inline offerings, whilst allowing the customer the best in cost, flexibility, and technology. We look forward to demonstrating these technologies to the visitors at this year’s event.”

The MV-6 OMNI 3D AOI machine is configured with the company’s OMNI-Vision 3D Inspection technology that combines the 15 mega pixel CoaXPress camera technology with 8 projection digital multi-frequency Moiré 3D system in a newly designed cost-effective platform. The CoaXPress vision system is a proprietary camera system that was designed and manufactured to use with the complete product range of 3D inspection systems. The Moiré technology provides true 3D inspection to yield precise height measurement data used to detect lifted component and lifted lead defects, as well as solder volume post reflow. Fully configured, these machines feature four 10 mega pixel side-view cameras, in addition to a 15 mega pixel top-down camera.

The MS-11e 3D SPI machine is configured with the 15 mega pixel CoaXPress vision system, providing enhanced image quality, superior accuracy, and fast inspection rates. The machine uses Dual Projection “shadow free” 3D Moiré technology combined with a Precision Telecentric Compound Lens and Precision Laser PCB Warpage Compensation to accurately characterize each solder deposition post screen print. This SPI machine precisely measures solder volume, area, shape deformity, and X/Y position and inspects for bridging between adjacent solder depositions. Furthermore, it provides real-time closed loop feedback to the screen printing system to effectively eliminate defects before they occur.

The MV-3 OMNI desktop 3D AOI machine is configured with the OMNI-Vision 3D Inspection technology which combines the 18 mega pixel CoaXPress industrial camera technology with the 8 projection digital multi-frequency Moiré 3D system in a desktop platform. Fully configured, the MV-3 OMNI machines feature four 10 mega pixel side-view cameras, in addition to the 15 mega pixel top-down camera. There is little doubt that this technology will set the standard by which all other inspection equipment is measured.

For the first time, the company will introduce the MV-9 SIP (System in Package) inspection system specializing in CSP components utilizing the 25 mpx camera with combined 2D and 3D inspection technologies. The system is able to handle 0.1 mm ~ 3 mm thicknesses via a vacuum block.

The company’s total quality management system software, Intellisys will also be on display at productronica. This software suite promotes continuous process improvement by allowing manufacturers to track and eliminate defects on inspected assemblies.

productroncia, Booth A2.329