SEHO Systems GmbH, a manufacturer of complete solutions for soldering processes and automated production lines, will focus on automatic process control at the upcoming SMT Hybrid Packaging show, scheduled to take place May 16–18, 2017 at the Messe in Nuremberg, Germany. The selective soldering system SelectLine-C has been even further optimized.

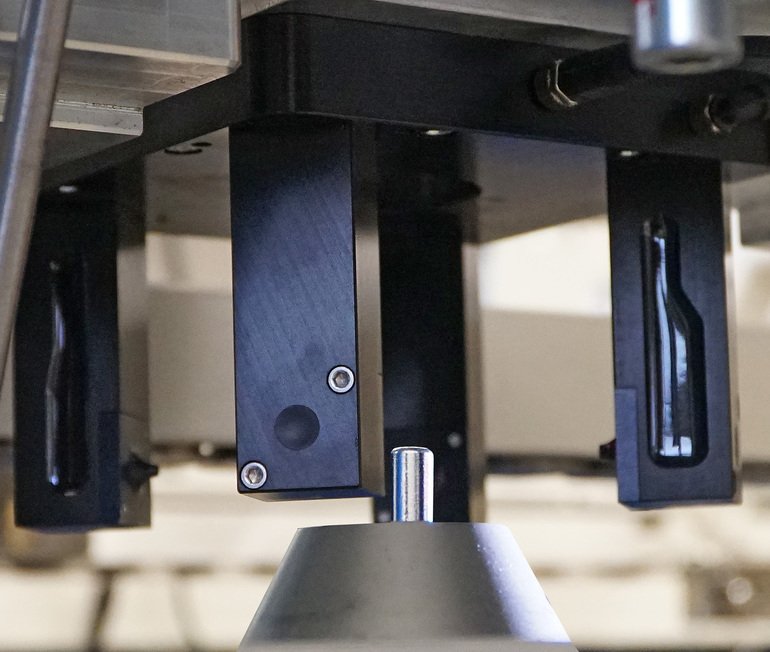

The company will introduce its new cross sensor at the exhibition that takes over several functions. On the one hand, the wave height is precisely controlled. The measurement is made touchless directly at the solder nozzle and it is fully independent from the solder alloy used. In addition, the cross sensor is also used for automatic tool measurement: diameter, height and mounting position of the solder nozzle are automatically controlled, thus excluding potential operator errors.

Also new, being introduced for the first time is an automatic nitrogen flow quantity control.

The company offers the opportunity to integrate additional processes directly into its selective soldering systems. This includes, for example, a brush system for solder joint cleaning or an AOI system for automatic detection of soldering defects. The benefits are obvious: no additional floor space is required in the production area. At the same time, production costs will be reduced as the entire board handling is performed by the axes systems that are integrated in the selective soldering machine anyway.

By adding an intelligent handling concept, assemblies that have been identified as defective can automatically be removed from the production line.

The new process control functions ideally supplement already existing features such as flux quantity monitoring, monitoring of the nitrogen quality or the automatic position and z-height correction thus ensuring a 100 % process control.

SMT Hybrid Packaging, Booth 4–129

Share: