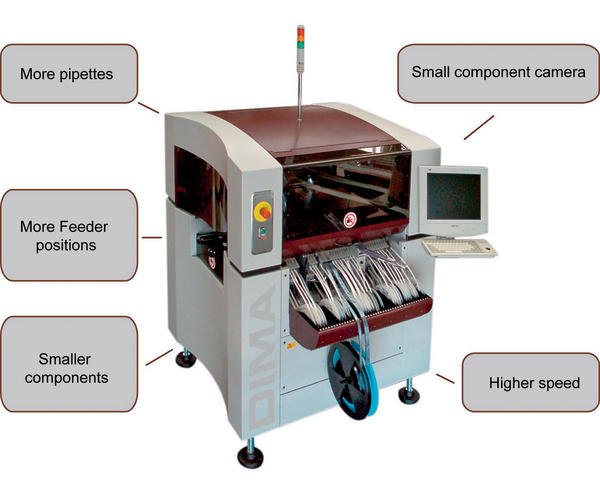

When starting up a production-line for manufacturing electronics you need to consider your current needs, but you should not forget about what might be needed in the future. Flexibility is the key word. What is not needed today, might be needed tomorrow. Still the level of investment in many cases is the bottleneck in the decision making process. DIMA has developed the HP-090 and HP-095 (stand-alone and in-line) modular pick & place machine. According to the company the machine can be the basic start for any manufacturer of electronics which can grow along with new requirements in the future. The modular pick & place machine uses the same software and full intelligent feeder concept of the HP-100 and HP-110. The new machine models have many similarities with the HP-100 and HP-110 such as the minimum and maximum pcb-size and over all machine dimensions. Also the placement accuracy of 50 µ at 3 sigma is guaranteed. The HP-090 and HP-095 have a component camera standard in order to be able to recognise components varying from 0402 up to components with a size of 42 x 42 mm. Co-planarity of fine pitch components and the usage of BGA’s are covered with this camera as well. The design of the feeders allows components up to 12 mm high and by utilizing a tray-platform components up to 16 mm can be handled in this machine as well. Both new models have one feederbank standard with 44 positions for the company’s full intelligent feeders. These feeders do not only guard the amount of components still available on a reel, but also contain information like component name and package. The feeders can be plugged in or out the machine in any random position at any time during production without interfering the production process. This utilizes the possibility to change an empty reel, or to setup a next set of feeders during production without stopping the current production. The 8 and 12 mm feeders take up only 1 feeder position. The speed of the HP-090 and HP-095 is up to 3.000 cph according to the IPC standard IPC9850. Both models can be upgraded in the field in a variety of steps. The available upgrades will provide expansion of the amount of feeder positions up to 132 feeders, usage of 0201 and 01005 components and a speed increase up to 4.600 cph. In combination with the firm’s cad-converter software and offline feeder programming station a zero change-over time can be guaranteed.

SMT, hall 7, booth 243

EPP Europe 446

Share: