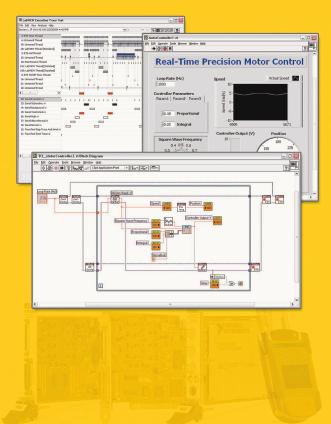

National Instruments has provided a significant upgrade for its test and measurement software package LabView. Reportedly, this leading program has the largest amount of installations in T&M systems on a global scale, used by numerous system integrators to realize demanding solutions, while keeping the costs affordable. Together with this outstanding package in the area of “virtual instrumentation”, an almost endless list of controller and I/O cards available, which are regularly being updated. The graphical development software version LabView 7.1 extends the technology of the recently introduced Express software to automated instrumentation and real-time applications with virtual instrument drivers (VIs) for modular instruments and data acquisition, advanced debugging and low-level execution timing.

“Last year, LabView 7 Express introduced a revolutionary way to create test, measurement and control applications with configuration-based development and code-generation tools,” said Ray Almgren, VP of product marketing. “By extending Express technology to the broad spectrum of automated instrumentation, LabView 7.1 simplifies development for all users, regardless of their hardware platforms”. NI continues to advance automated instrumentation for hardware platforms ranging from high-performance modular instruments to real-time data acquisition systems and handheld devices. With five new Express VIs for digitizers, signal generators and high-speed digital I/O, users can configure sophisticated measurements and acquire data with just a few mouse clicks. The redesigned DAQmx software, available in real-time applications for the first time, increases performance of single-loop PID applications by 30% and simplifies hardware-timed loop implementation. In addition, a PDA module delivers more data-acquisition functionality, including faster multi-channel functions as well as analog and digital triggering. Engineers can use this module to create handheld DMM applications and communicate with Bluetooth-enabled devices.

The program also introduces advanced execution timing and graphical debugging for low-level control and visibility of real-time execution. With the timed loop, users can specify precise timing of code segments, coordinate multiple time-critical activities and define priority-based loops for creating multi-rate applications. To further optimize performance of their applications, engineers can use the execution trace toolkit with the real-time module to quickly identify sources of jitter, such as memory allocation and race conditions. In addition to speeding development of real-time applications on existing platforms, release 7.1 extends real-time applications on certified desktop PCs, allowing creation of those systems by integrating the large base of PCI I/O hardware.

The FPGA module, which is also released with the package, improves efficiency and functionality of embedded FPGA applications. It features single-cycle with loops that execute multiple functions within a single 25ns “tick” of the 40MHz global clock. With this feature, engineers can develop FPGA code that executes as efficiently as hand-coded VHDL. They also can reuse their existing VHDL code in LabView FPGA applications with a HDL interface node.

EPP EUROPE 412

Share: