Since the RoHS (Reduction of Hazardous Substances) directive prohibits the use of lead, cadmium, mercury and chromium (IV) compounds in the PCB production und board assembly, circuit board producers have to switch from the hot-air solder leveling (HASL) to lead-free alternatives. HASL has failed to meet SMT and COB requirements for evenness of surface.

Basically, the following lead-free surface finishes may be considered for circuit boards in general: HASL; OSP (organic solder preservative); chemical nickel/immersion gold; chemical nickel/chemical palladium/immersion gold; immersion tin; immersion silver; and electrodeposited tin. According to estimations, application of HASL and OSP surfaces in Europe will decline from approximately 87% (2003) to 52% (2007). Immersion tin is expected to increase from 2% (2003) to 32% (2007). On a global scale, the distribution of surface finishes is forecasted for 2007 as follows: HASL 20%; OSP 34%; chemical Ni/Au 12%; immersion-Ag 17%; and immersion-Sn 17%.

PCB fabricator Ruwel can reportedly offer HASL, OSP, chemical Ni/Au, immersion-Sn and immersion-Ag, and has some experience with chemical nickel/chemical palladium and immersion gold. The high cost of electro deposition leads to low market acceptance, despite its good surface quality that is solderable and bondable. The electrodeposited tin has the drawback that, after etching, the conductor edges are not protected, and that tin overhangs from the etching process can break off.

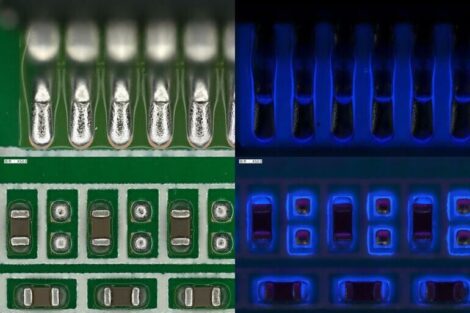

With HASL, the PCBs are coated with molten solder on a tin-lead or lead-free basis. However, the surface shows an uneven coating thickness which is unsuitable for SMT and bonding. Fab lines are available for surface coatings based on copper with organic passivation. These OSP-surfaces are not bondable. Because of temperature-sensitivity reasons, multiple soldering should be carried out in a nitrogen atmosphere. OSP is suitable for lead-free soldering.

The chemical nickel-gold surface is suitable for Al-wire bonding and is compatible with lead-free soldering. Due to low demand, Ruwel does not operate a plant for PCB coating with immersion silver. The process has been tested and shows good solderability, also in regard to multiple soldering using lead-free soldering.

Immersion tin as a lead-free surface finish is accepted by the industry and regarded as a viable alternative to HASL. Initial problems with whiskering have been tackled and solved. The tin surface is suitable for multiple soldering using lead-free technology. A minimum coating thickness of 1µm Sn is required for lead-free. The coating is applied in continuous horizontal lines. The company claims to guarantee solderability of immersion tin coatings after a one-year storage period, provided the following criteria are met: storage conditions 23°C ±2K; relative humidity 50% ±6%; coating thickness 1µm; and hermetically sealed vacuum packing. The conditions are in conformity with DIN 50014–23/50–2 (storage of PCBs in a standard atmosphere).

EPP EUROPE 415

Share: