Today’s production managers are under tremendous pressure to do more with less, maximize profits and maintain the highest quality standards. Companies that want to exist on the global market are forced to apply production methods that have to be fast, flexible and extremely reliable. Costreduction, process quality and versatilityare only a few parameters that affect mission critical electronic products. It thereby becomes apparent that more attention needs to be paid to the device programming equipment used within the production environment. A checklist by Data I/O Corporation.

Data I/O GmbH, Gräfelfing (Germany)

We are rarely without electronic devices today and to some extent modern day electronics are all mission-critical. Today, mission-critical electronics have become integral part of our everyday lives. When driving down the road at 60 miles/hour the ABS system cannot be rebooted. The brakes need to work every time. When checkingblood sugar before a meal the glucometer cannot be recalibrated. Accurate results are needed. When stranded in a snow storm or have been involved in an accident, the mobile phone needs to work flawlessly.

Today consumer electronics safety is in the hands of industry experts in both product design and manufacturing. The first step in protecting mission-critical electronics are to identify key components that if they fail can becatastrophic and possibly result in the loss of life. Programmable devices including logic, flash memories andmicrocontrollers are the first components put on the mission-critical list. Device programming is the foundation and the critical first step to ensure product quality, reliability and safety. Programming a device with a poorly developed algorithm, an algorithm not written to spec. or noisy programming signals are an accident waiting to happen. Choosing the right programming equipment is a matter of life and death. Production managers are under tremendous pressure to do more with less, maximize profits and maintain highest quality standards. The following checklist is useful to evaluate offline automated programming equipment.

Programming velocity

Programming engine: The programming engine is the CORE of every automated programming system. Choosing the right programming engine can save time and money down now and in the future. The ideal programmer supports both legacy (1980’s – 1990’s) and thelatest memory, microcontroller and logic devices.There aremore than 10,000 different programmable devices that existtoday. It’s more important to find programming engine that supports both your current and future device support needs. Growing image sizes require fast programming speeds to achieve desired levels of system throughput (parts per hour). Comparison of program/verify speeds required, the closer they come to theoretical programming speed capabilities of modern devices, the better. Download speeds have a direct impact on changeover time. The larger the image files, the longer the download time. If programming large files, it is good to make sure the programmer supports fast downloads. Look for a programmer that supports performance enhancements via software updates rather than hardware. Software performance upgrade times are faster, cost less and have minimal impact on production, as compared to hardware upgrades.

Throughput (device per hour): It is good advice to do an apples-to-apples comparison on system throughput. Many factors impact system throughput, including image filesize, file download time, programming speed, mechanicalhandling time, number of pick-and-place nozzles and the media and marking options in use. The vendor should be able to tell what throughput can be expected based on the image file size, I/O media and marking requirements. The equipment has to be built in capacity to support unexpected ramps in production. Image file size, filedownload, programming speed, mechanica lhandling, media options, marking &socket capacity impact throughput calculations.

When programming small files with short programming times, the handling time is the limiting factor in determining system throughput, not the number of sockets. The handling time is the time it takes to remove a device from the input media, place itinto a socket then remove it from the socket and place it into the output media. The Pick and Place (PnP) assembly i.e. in the comapny’s latest generation automated programming and handling system PSV7000 is carried on linear guides and not by X-Y drives resulting in less wear while delivering superior positional repeatability and accuracy at ±0.030mm. Linear X-Y encoders with resolution of 1 micron (1uM) provide real position of the PnP. Compliant pick-and-place nozzles, similar to those used on flexible high-speed SMT placement machines are available to support the smallest programmable device.

Programming large files with long programming times, the number of sockets and the programming speeds are the limiting factors in determining system throughput, not handling time. A well engineering robotics system is going to perform all handling functions from within the main work envelope. Impacts to system throughput include moving to an upwardcamera for alignment to sockets, marking, vision inspectionand handing off to options. Look for a programmer that supports performanceenhancements via software updates rather than hardware. Software performance upgrade times are faster, costs less andhave minimal impact on production, as compared tohardware upgrades.

Versatility

Scale to demand: System scalability and programmer capacity should always get factored into the buying decision. A system should be configured to meet programming capacity for today and in the future. Profiting from unexpected ramps in production requires configurable manufacturing. Having the ability to quickly reconfigure a system versus the costs and delays associated with acquiring additional capital equipment is huge, not only in profitability but also in capturing market share. It’s more cost effective to add extra programmers to support future ramps in production than purchasinga new system. Benefit from cost savings associated with floor space, maintenance and labor.

Minimize floor space and maximize programming: Input output media, marking and vision inspection options vary from one supplier to the next. A concurrent media configuration requiring no mechanical changeover is going to deliver higher uptime performance than those without. Programmer scalability cannot be understated. Substantial cost savings are realized by simply adding programmer capacity to an existing system as compared to the purchase price and floor space requirements for a new handler. A scalable handler with the maximum programmer capacity requires the least amount of floor space. Only a few programmers may meet current demands. System flexibility in general refers to the options available to support different applications along with the changeover times associated with each option. Systems with integrated media options that minimize changeover increase throughput. Substantial cost savings are realized by simply adding programmer capacity to an existing system as compared to the purchase price and floor space requirements for a new handler.

Value: Price is what you pay, value is what you get

Supplier Credentials: A trusted supplier should be reliable, knowledgeable and have an understanding of business requirements. Capital equipment investments are a huge undertaking and it is important to know what to ask when looking to purchase offline automated programming system is critical. If the initial purchase price is the only research factor, shelling out less money up-front may turn into a lot of cash and headaches down the road. One of the aspects of being successful in business is producing a quality product as cost effectively as possible. Reliable suppliers have the flexibility to work with customers to meet their production requirements. Unreliable suppliers who cut corners and cannot keep up with demand can ruin business.

A supplier has to be known to have consistent quality products. If quality falls from time to time it impacts business reputation and the relationship to customers. A research of the company’s history and financial position might be necessary. Suppliers need to manage their product, people and equipment, too. If they do cut prices down considerably, just to get business, they may not value customers’ business and thus, the quality and reliability may be lacking.

It is useful to contact and identify two or more programming equipment vendors for evaluation. Close analysis is required to ensure the best return on investment (ROI) decision is made. To be an informed buyer, it is important to review not only the price, but the quality, design, safety features and overall investment. If these factors are not considered, the lowest quote may not be the lowest price in the end.

Device support strategy: Programming equipment without device support is like a razor without blades. Device support consists of the programming algorithm, socket adapter plus any special features and/or bad-block management software. Understanding customers’ current and future device support requirements can save millions of dollars down the road. Not all algorithms arecreated the same. For the highest quality algorithms written to the manufactures current specification with a trusted programming engine are helpful. Semiconductor manufacturer are constantly updating their devices and specifications. An annual contract ensures to have the most up-to-date algorithm.

Factors that can impact a supplier’s ability to deliver timely device support include poor processes, limited resources, multiple programming engines, device specific complexities, socket availability and/or turn-times for adapter circuit boards. For mission critical applications, quality programming algorithms can mean the difference between life and death. It must be verified that all programming algorithms are written according to the manufacturers’ specifications. A good device support process will have feedback loops providing project status updates. Tools that encourage collaboration can significantly speed up device support delivery. Device support is a sustaining effort requiring highly skilled software engineers for development and maintenance. Caution should be given to any company laying claims to “free”device support. Programming equipment suppliers require sample devices and specs to add new device support. Semiconductor vendors enhance their silicon for a number ofreasons including adding new features, improving performance and/or correcting errors. Any reputable programming equipment supplier will offer device support contracts providing user access to the latest programming algorithms. Parts programmed using the wrong or outdated algorithm especially in mission critical applications can be catastrophic.

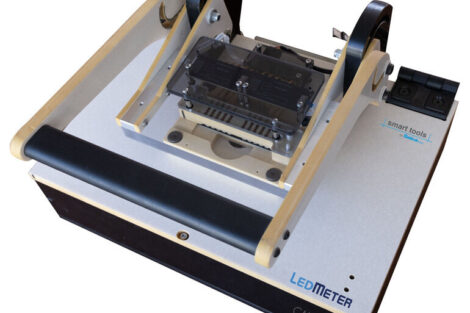

For all these reasons the right programming equipment delivers advantages customers need to succeed in today’s global markets. A high quality programming process ensures electronic products to work when and where they have to. The company lately introduced the automated programming system PSV7000 designed to exceed the most demanding programming requirements. It is capable of programming up to 2000 devices/hour with tray, tape or tube input, and can handle the smallest programmable devices on the market including SOT packaging and smaller. The system small parts handling capabilities utilize state-of-the-art laser alignment, motion control and pick-and-place technology all built around a stable platform to deliver the best small parts performance. Changeover times have been reduced by up to 75 percent compared to other systems. High-precision laser marking, 3D co-planarity, serialization and traceability software are available options to support the highest quality process requirements.

Checklist: What should be considered?

Velocity

⃝ Programming Engine

⃝ Throughput (Devices per hour)

⃝ Changeover Time

⃝ Uptime

Versatility

⃝ Scalability

⃝ Flexibility (Tubes, Trays, Tape and Reel, Marking Vision Inspection)

⃝ Programming Capacity

Value

⃝ Supplier Credentials (Company Background and History)

⃝ Device Support Strategy

⃝ Programming Yields (Socket Adapters)

⃝ Floor Space Requirements (Footprint)

⃝ Warranty

⃝ Service and Support

⃝ Quality and Reliability

⃝ Return on Investment (ROI)

Zusammenfassung

Mehr denn je stehen Elektronikhersteller bei der Programmierung der eindesignten Halbleiter wichtigen strategischen Entscheidungen gegenüber, die deutliche Konsequenzen für die Fertigungsqualität und -flexibilität haben. Der Artikel stellt einen Kriterienkatalog dar, um bei der Bewertung von Programmierequipment unterstützen zu können.

Plus que jamais, les fabricants d’électronique se voient confrontés lors dela programmation des semi-conducteurs intégrés au design, à des décisions stratégiques importantes qui ont des conséquences manifestes pour la qualité et la souplesse de fabrication. L’article représente un catalogue de critères pour apporter une aide lors de l’évaluation de l’équipement de programmation.

Share: