Flying Probes are currently used to test boards both on commercial and military products for prototype verification, production or depot repair. Costly, high quality and high reliability products such as boards hosted on satellites present a number of specific challenges. They include overcoming physical access limitations, accuracy and repeatability of probing, prevention of any mechanical or electrical degradation, thoroughness of test. This article addresses the solutions to these requirements based on a successful customer experience.

Andrea Romano, Sales Technical Support, Seica

It was an unusual challenge for the company when they received a request to provide a flying probe solution to test boards for satellites. Of course the company had good experience on similar applications, having installed a number of flying probes in mil/aero environments, for prototype validation, for production or for field return test and repair depots. If our solution was excellent for airplanes, why not for satellites? Yet, the request to test boards that had to go up permanently in the sky, mostly on communications satellites, had something exciting about it, and soon revealed to have a number of particular challenges. Boards for satellites are very sophisticated and have extremely high requirements for reliability (they are complex, highly integrated and…you can‘t go and fix them once they are up in the sky!). Furthermore, they are very expensive and one will be careful not to damage a single board that can cost as much as the tester! The customer had indicated the main reason of his interest in our equipment; his boards were very densely packed, for obvious reasons, with components on both sides and a limited number of test or via points. Hence, a flying probe assuring full test access on both sides of the board was an indispensable requirement, and the Pilot V8 model was perfectly addressing it. The Pilot V8 is a flying probe test system featuring four independent test heads on each side of the board under test. The test heads provide, on each side, the electrical probes, the colour cameras and other optional probes for capacitive test, for laser test or for thermal test. The system can provide a wide range of power-off parametric and in-circuit tests, as well as functional tests with power applied to the board, JTAG tests, On-Board-Programming. The Pilot V8 architecture, unlike conventional flying probers, loads the board under test vertically, to minimize the impact of mechanical vibrations during test and assure fast and repeatable results.

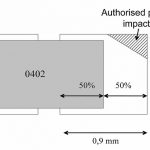

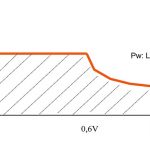

But the customer‘s needs did not stop at dual-sided test access. Since test points are limited on his boards, it was allowed to probe on the solder side of some components, currently 0402 discretes, with smaller sizes like 01005 coming for future boards. However, the landing area for the probe had to be on a limited side of the solder, a little triangle defined by the customer, and minimal physical impact from the probes had to be assured. Using 3 mils, single tip nails, we proved absolute repeatable results with spread of impacts centered on the area between 5 µ and 40 µ. Furthermore, the system was controlling soft landing, grouping tests on a single contact, spreading the impacts on different points of a net and controlling, with optional limits, their number on the same point. Being reassured about mechanical precision and lack of damage to the board, the next request was to limit the power applied during test. The customer‘s intention was to perform only power-off tests on the components of the board with the constraint that injected voltage, current and power were always limited. Selected tests included net-impedance and shorts tests, discrete in-circuit tests, capacitive tests for opens and other complementary tests. To fulfill this requirement during test generation, debug and execution, the company introduced micro-code modifications to the DSP of the stimulus and measurement system, to limit voltage to 1 V, current to 10 mA and maximum power to 6 mW. Finally, a number of test scenarios were simulated to stress the test system reaction in case of power failures or other unexpected events and assure that the test sequence was safely interrupted without any damage to the board under test.

With active customer cooperation, we ran tests and verifications for over two months, with boards being accurately verified after each run of tests, until the solution was officially approved. A special frame was also designed to properly host the boards and assure precise positioning on the tester. After an initial period of using the system, the customer gained further confidence in the solution: they have subsequently upgraded the system capabilities to power-up the board under test and run thorough functional tests, taking advantage of the extended access enabled by the flying probe. All the solutions implemented on the system are now standardized for all of our equipment. So, from the flying probe….up to the sky.

Share: