The requirements on adhesive dispensing in a multitude of electronic applications continue to increase, where reproducibility of minute volumes, stability of the drop and high process speed are mandatory.

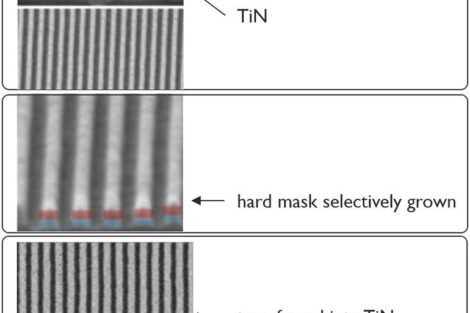

A dispensing method that suits many production processes is the Delo-Dot; using this non-contact approach, the Z-axis with the needle tip does not have to be moved during dispensing. It is therefore not only possible to achieve a high dispensing speed, but at the same time a more reliable process as well. The valve operates with a piezo actuator as the compelling element. With piezo actuators arranged in parallel, the valve can be opened and closed via a lifter mechanism and a long needle. A small ball is located at the end of the needle, which bangs on the nozzle. Both components, ball and nozzle, are made of abrasion-resistant ceramic. Through high-speed compression and decompression of the piezo-actuators in less than 100 µs, the adhesive inside the nozzle seat receives such a strong impulse via the ceramic ball that it is ejected from the nozzle at very high speed (jetting). This way, a high positioning accuracy of the drop is achieved, even at a distance of 10 mm. The cycle can be repeated up to 250 times per second. The amount of adhesive and therefore the size of the drop is determined by following characteristics: stroke of the piezo, open time of the valve, and the pressure and temperature inside the cartridge.

The dispensed adhesive quantities or drop sizes depend strongly on the medium, but a minimum down to 0.003 mg can be realized. The viscosity of different materials can vary, for example, by a factor of 2000, but this does not necessarily mean that a dispensed quantity is 2000-times higher. It increases just by a factor of 10, due to different thixotropic effects in the adhesive. The accuracy of dispensed volumes is in the range of ±1.5 %. Each valve is controlled by a unit, monitoring the piezo stroke, the open and cycle times of the valve, and the adhesive temperature. A control box is driven via a process generator, the Delo-Protor 2, or by a program-controlled system. The process generator is able to steer two valves either in parallel or independently from each other. The programming of the generator is performed through a Windows PC. For each valve, up to ten different programs can be stored and accessed. Communication proceeds via RS232-interface. All programs can be individually started via different signals from the process generator. After completion of a dispensing task, a signal is returned, allowing integration of several dispense valves into one process. Any number and size of adhesive drops can be generated. Different dispensing tasks, which often have to be performed on the same board assembly, can thus be easily realized.

EPP EUROPE 462

Variable drops – applied within one program step

Share: