Temperature plays an important role in many fields of the industry. Constant temperature is essential and requires targeted heating and/or cooling of components, tools and materials in industrial and medical applications. The choice of the right solution to achieve this tempering depends on the specific requirements of the application, like for example the material, the temperature range, the design or the required capacity.

Flexible heaters derive from the field of flexible PCB technology and were first developed in order to solve problems in high-tech sectors like aerospace or medical technology. Like for PCB, most of the heating lines are produced by etching. This involves features like short preheating time and a long life time.

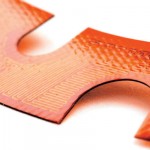

Flexible heaters

Flexible heaters are advantageous whenever target and constant surface heating is required. Depending on the application area, the supports and insulation materials are mica, polyimide, silicone and polyester with heating capacity up to 17 W/cm² (mica). Mica heaters are fixed mechanically whereas the other materials are usually fixed with a self adhesive film. The great advantage of this solution is the free disposition of the heating output as well as the really good allocation of temperature all over the flexible heater. Self regulated flexible heaters are simplifying the tempering enormously because neither temperature sensor nor temperature switch is needed anymore for monitoring the temperature. This results in completely new applications which weren’t possible in the past.

Advantages:

- Little weight, space-saving

- Flexible, rugged, reliable

- Different shapes and dimensions

- Low consumption costs

- Homogenous energy distribution

- Constant surface temperature

- Precise heating distribution

- Short preheating time

- Different temperatures for one flexible heater

- Long life time

- Easily mounted

Applications:

- Medical technology: for example, polyimide-flexible heater for tempering of blood test or medical equipment

- Analysis technology: for example, silicone-flexible heater for heating of supporting mediums in analysis devices

- Apparatus engineering/ machine construction: for example, polyimide-flexible heater or silicone-flexible heater for packaging machines

- Aerospace industry: for example, polyimide-flexible heater to de-ice propeller; successfully used for space flight

- Optical industry: for example, Polyester-flexible heater for heating of safety glass

- Telecommunication: for example, polyester-flexible heater for heating of LCD-displays or polyimide flexible heater for heating of dish antennas

- Catering: for example, polyimide flexible heater for hot plates or coffee machines

- Private households: for example, silicone flexible heater for heating of bathroom mirrors

- Application for liquids: double-insulated flexible heater for PVC cover – sandwich construction ensures a reliable functionality, for examle, underwater applications

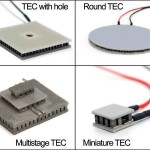

Peltier thermoelectric coolers

The basic idea behind the Peltier effect is that whenever DC passes through the circuit of heterogeneous conductors, heat is either released or absorbed at the conductors‘ junctions, which depends on the current polarity. The amount of heat is proportional to the current that passes through the conductors. A typical thermoelectric cooler consists of thermocouples connected electrically in series and sandwiched between two Alumina ceramic plates. The number of thermocouples may vary greatly – from several elements to hundreds of units. This allows to construct a TEC of a desirable cooling capacity ranging from fractions of Watts to hundreds of Watts.

When DC moves across the module, it causes temperature differential between its sides. As a result, one side, which is called cold, will be cooled while its opposite face, which is called hot, is heated simultaneously. If the heat generated on the hot side is effectively dissipated into heat sinks and further into the surrounding environment, then the temperature on the cold side will be much lower than that of the ambient by dozens of degrees. The TEC’s cooling capacity is proportional to the current passing through it. Its cold side will consequently be heated and its hot side will be cooled once the polarity has been reversed.

The typical dimensions go from 4 x 4 mm up to 62 x 62 mm with a thermal pumping capacity going from 0,4 to 230 W. The maximum working temperature runs from – 40 °C to + 200 °C. The design is there not predetermined. The modules are available in special designs with different length, width and layouts. A multitude of cooling systems is possible to achieve with Peltier thermoelectric modules. Only the cooling of the warm side is decisive. The colder you can keep the warm side; the colder the cold side can get in order to ensure the desired cooling. Therefore, the transported heat flow volume going from the hot side to the cold side of the thermoelectric cooler has to be transferred to the full extent. This can be reached e.g. thanks to fans or water cooling.

Advantages:

- Highly reliable

- High-performance

- Vibration free

- Space saving

- Silent and economical

- Non-moving components

- No cooling liquid necessary (environment-friendly solution)

Applications:

- Electronics: cooling of HF-components, power-transistors, laser-diodes, highly sensitive radio-receivers as well as other electrical devices which need to be cooled in affordable ways.

- Air-conditioning: air-conditioners for stabilization of humidity and temperature

- Medical- and Lab-Technique: cooling of solid or gas-liquid medium for cosmetic or medical refrigerated containers, thermal calibration and refrigerated desks.

Cooling units based on Peltier technology

Demands for increased performance implicate increased sensitivity to temperature in electronic components; therefore a stable, consistent temperature is required. This can be easily achieved with Peltier cooling/heating units, offering a reduction in production failures and the associated higher costs. Peltier modules play a similar role to traditional compressors or absorbers, like those used in typical refrigerators. However Peltier modules deliver affordable performance against these and other comparable traditional technologies. These products are available in different versions, from 75 W to 380 W.

Peltier-cooling-units consist of Peltier modules, cooling unit and fan. The Peltier module acts as heat pump assisted by a thermoelectric heat flow, which dissipates the heat from the cold-side to the warm-side of the module. The thermal management on the warm-side is the determining parameter for every application. The lower the temperature can be held on the warm side of the module, the cooler the cold side, the better the performance. Therefore the heat has to be dissipated completely from the cold side to the warm side of the Peltier module. The combination of cooling-body and fan ensures the best pumping performance on the cold-side and avoids over-heating of the Peltier module. The current flow can be reversed by a pole reversal of the Peltier modules. Warm-side and cold-side are exchanged and the cooling unit becomes an air-conditioner.

Advantages:

- Cooling and heating by means of Peltier-technique

- Non-movable parts (except wheel of the fan)

- No liquids or cooling liquids (environment-friendly solution)

- Very low noise level

- Compact size and low weight

- Easy handling

- Precise regulation of temperature

- Usable in nearly every position

Applications:

- Constant temperatures for switch cabinets

- Climate control of rooms with electrical devices

- Units for temperature conditioning

- Transport of refrigerated organic material and fluids (e.g. conserved blood) in mobile refrigeration containers

- Cooling chambers

- Temperature controlled chambers

- Thermal-calibrators and thermostats

- Portable fridges and refrigerated boxes in different sizes (e.g. picnic-boxes)

- Refrigerated containers for cafés or stores

- Thermo-electrical air conditioners with fans

- Temperature stabilization for terrarium

EPP Europe 431

zusammenfassung

Die richtige Betriebstemperatur ist häufig Voraussetzung für erhöhte Betriebssicherheit und längere Lebensdauer der Elektronik. Die zunehmende Leistungsfähigkeit der Elektronik führt zu einer höheren Sensibilität der Bauelemente gegenüber Temperaturen. Daher ist eine gleichmäßige, stabile Temperaturverteilung erforderlich. Diese wird z. B. mit Peltier-Kühl-/Heizaggregaten erreicht.

Une température de fonctionnement correcte est souvent indispensable pour garantir une fiabilité et une longévité élevées des composants électroniques. Les performances croissantes atteintes dans le domaine de l’électronique impliquent une sensibilité accrue des composants à la température. D’où la nécessité d’une répartition de température uniforme et stable. Un objectif réalisable par ex. avec des modules Peltier de refroidissement/chauffage.

La temperatura di esercizio corretta è spesso un requisito che garantisce una sicurezza di esercizio elevata e una maggiore durata dei componenti elettronici. L’aumento di efficienza dell’elettronica comporta una maggiore sensibilità alle temperature dei componenti. È quindi necessaria una distribuzione uniforme, stabile della temperatura. A tale scopo si utilizzano, ad esempio, gruppi di raffreddamento/riscaldamento Peltier.

Share: