Testing lead free soldered pads or strongly contaminated or oxidized boards often leads to contacting problems, because the different contamination or oxide layers are difficult to penetrate and the probe tips themselves are contaminated very quickly. Both leads to a affected electrical contact – or even to a complete contact loss in the connection to the test item: A nightmare for all manufacturers of electronic devices, who need to test their boards fast and reliably and do expect a long durability of the contact probes used. A detailed analysis of these problems results in different aspects to be considered and resolved.

Volker Großhans, Feinmetall, Germany

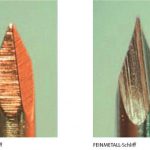

In order to penetrate strong contamination and tough layers reliably, a contact probe must have a very aggressive tip. Not only the form of the tip is crucial, but also the microstructure of the material. Optimal results can be attained by a special longitudinal grinding in combination with a concave shaped tip style.

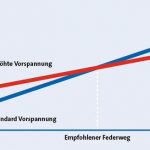

A further crucial aspect for penetrating contamination or oxide layers is the optimal contact force: The higher the contact force, the better the penetration. However, in practice the maximum total force is limited by the test fixture, since otherwise the adapter cannot be closed reliably or the tested board is loaded too strongly or even damaged. A solution is the use of contact probes with increased preload. Thus a more intense force during the contacting process is realized and the penetration is much better, while the nominal spring force at the recommended travel remains unchanged compared to conventional probes. So these probes can be used even for test fixtures with a higher number of test points without causing any force issues. Extensive tests showed also in practice that the higher preload results in a better penetration of the oxide coatings without increasing the penetration depth in the tested board. So, the use of probes with higher preload does not increase the danger to damage the test items.

Optimization of the contact force

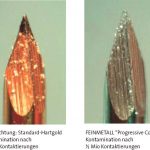

A further problem in particular with the contacting of lead free soldered pads represents the intensive contamination of the tips. At conventional contact probes these contaminations stick to the probe tip and lead to a substantial increase of the electrical resistance. So often a premature exchange of the pins is necessary. This can be avoided by using probes with a functional coating that results in a substantially reduced susceptibility for contamination and at the same time an increased hardness in relation to conventional gold plating. Thus a remarkably longer lifecycle of the probes can be obtained.

Reduced contamination of the contact probes

All these features are realized in the new Feinmetall „Progressive Series Probes“, and the success has been proven in the field. Various important customers have equipped their test fixtures with the Progressive Series Probes – and are more than satisfied with the results: Lifetime and contact quality increased by conversion to these probes. Thus clearly improved FPY (First Pass Yield) values are reached. The FPY characterizes the percentage of test items, which are correct in the first process run and do not require further rework.

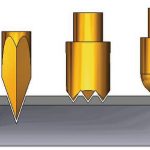

Correlation of tip style and spring force

The penetration depth of a probe considerably depends on the spring force and the selected tip style. The more aggressive a tip style is, the better it can break through contaminations, however at the same time the deeper it penetrates the tested board. In order to avoid damages on the PCB, tip style and spring force must be selected carefully.

Zusammenfassung

Verunreinigungen der Kontaktstellen oder an Prüfspitzen können die elektrische Verbindung zum Prüfling beeinträchtigen oder im Extremfall nicht herstellen. Die Analyse dieser Problematik ergibt verschiedene Teilaspekte, die genauer betrachtet und gelöst werden müssen.

Les impuretés sur les points de contact ou les pointes de sondes peuvent réduire la conduction électrique avec l’échantillon ou, dans le cas extrême, ne pas l’établir. L’analyse de cette problématique met en évidence divers aspects partiels qui doivent faire l’objet d’un examen plus précis en vue de leur résolution.

Share: