It is not just the automotive sector where the topic of stress factors and their resulting failures has gained in importance and electronic assemblies are being exposed to increasingly “undesirable environments”. Besides the mainly purely thermal processes combined loads must also be considered. On the one hand these are thermal cycles over a broad temperature range that lead to thermo-mechanical stress and on the other hand the combination of moisture stress on top of the pure thermal load, in particular dewing.

Additional osmotic processes may occur in the presence of dewing which can trigger off chemical-physical processes that would not arise in the case of high moisture loading. Besides the purely physical processes chemically irreversible degradation processes can also take place.

Corner thinning

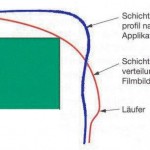

Dewing is an adsorption process whose negative effects on the electrical insulation can be securely avoided by the application of appropriate coatings. However, a reliable and adequate coverage of the current-carrying potentials is mandatory as shown in figures 2 and 3 b. Sufficient edge coverage – especially on angular component leads (see figure 3 a) – is not a trivial matter. The so-called “corner thinning” of liquid coating materials (figure 1 a) is a function of the radius of the corner and the surface tension. It also depends on the viscosity. The lower the viscosity, the greater and quicker the corner thinning. Corner thinning cannot be prevented by increasing the viscosity or flow threshold, it can only be delayed. Good edge coverage can be achieved through a high viscosity, high flow threshold, fast cure and no sharp edges. Unfortunately, sharp component leads are common and cannot be avoided. Ultimately, corner thinning always results in a reduced layer thickness along the coated edge. Significantly higher viscosities to delay corner thinning are incompatible with the standard application methods used.

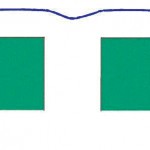

With solvent-based conformal coatings the layer thickness is not only reduced by corner thinning but also by the drying process. The resultant dry film thickness is around 50 % of the wet film thickness. It is not easy to apply thicker protective coatings of 100 µm and more. In a simplified estimate, one can say that approx. 200 µm of conventional wet ink must be applied in order to achieve a dry film thickness of 100 µm because conventional conformal coatings are made up of around 50 % solvents. These solvents evaporate from the film and thus reduce the applied layer thickness. Solvent-free thick film lacquers are advantageous in this respect since they “encapsulate” rather than coat the component leads so that corner thinning cannot take place (figure 1 b). Figures 2 and 3 b show such “mini-cast” component leads. As a result of the higher layer thickness applied such critical areas exhibit a significantly higher protective effect, in particular against dewing.

When looking at standard conformal coatings, the basic rule is that the ink film takes longer to dry the thicker it is applied. This is physically understandable since the solvents in the wet ink film must travel over a longer distance to escape from the ink film. Equally, with oxidative drying inks the oxygen must cover longer distances in order to cure the ink film thoroughly. These delays in the drying process are not simply linear, i.e. double the layer thickness does not mean double the drying time, but are exponential, i.e. double the layer thickness is more equivalent to around quadruple the drying time. The time required until the desired final properties, such as adhesion and electrical insulation, are reached is much longer and is also more sensitive to fluctuations in the film thickness which are always present on electronic assemblies. Moreover, the solvent retention makes such coatings especially sensitive to premature encapsulation, packaging or climate stress.

Solvent-free UV curing thick film lacquers, e. g. the Twin-Cure series, can be processed in the condition supplied. They are distinguished by their extremely fast curing cycle of under 1 minute. These materials can be optimally processed at a viscosity between approx. 80 and 150 mPas.

The advantage of a low viscosity is the ability to apply the ink by means of the standard selective coating methods and the improved and quicker wetting and/or underfilling of the components. Even with ink viscosities of around 80 mPas layer thicknesses of 80 to 120 µm can be achieved on unpopulated areas, thus equalling the protection of a thick film lacquer, while simultaneously fulfilling the desire for economic efficiency. For example, with the traditional film-coater layer thicknesses of approx. 100 µm can be achieved on bare areas resulting in a much more profitable coating with the same or an even better protective effect. As demonstrated in figure 2 b, the edge coverage and moisture insulation – e. g. on component leads – are maintained in terms of a “micro-casting”. The component leads are completely enclosed and the space under the leads is completely filled. The gap between casting compounds and conventional conformal coatings is closed both from the economic viewpoint as well as regards the protective effect.

It is not permissible to add solvents to such UV curing lacquers as they will become trapped in a more or less uncontrolled manner during the UV cure and evaporate erratically in the face of subsequent thermal loads. This causes shrinkage tension which weakens the coating. If a lower viscosity is required for processing, this is only possible by heating the lacquer. With some coating methods heating the lacquer can help achieve better coating results. It must be considered that the applied lacquer will be cooled down by the “colder” assembly, consequently causing the viscosity to rise again.

Viscosity and wetting

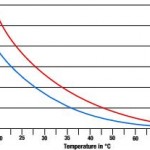

In particular solvent-free inks have a marked temperature-related viscosity. As a rule of thumb, one can say that the viscosity is halved if the temperature rises by 10 degrees or the viscosity is doubled if the temperature sinks by 10 degrees. While this effect can be successfully utilised to reduce the processing viscosity, it also means that the processing temperature must be kept consistent. Potential temperature fluctuations in the processing environment can be counteracted, for example, by working with a heated ink system so that the processing temperature lies slightly above the maximum room temperature (figure 3 a + 3 b). The viscosity (figure 4) reflects the typical temperature relationship. The temperature must not be raised above 80 °C. Over 80 °C the tendency of the lacquer to polymerise increases so that its secure processing can no longer be warranted.

Higher viscosity thick film lacquers also utilise the so-called capillary effect to fill the space under SMD components. The capillarity takes place by means of wetting a capillary (a space) with a liquid, i.e. by means of the surface tension. The liquid-relevant factors in this respect – expressed in terms of Washburn’s equation – is the contact angle of liquid and solid and the viscosity. The wetting depth lB within a given time unit is directly proportional to the liquid-solid interface tension (s LA) and to the contact angle (cos U) and inversely proportional to the viscosity of the liquid (h):

It can be derived from these proportionalities that a high surface tension of the liquid and a low contact angle with the solid surface are decisive for quick penetration. Unfortunately, neither prerequisite can be fulfilled under normal circumstances; it is clear that a low contact angle is a major requirement. That means that a droplet on the surface should have as flat a shape as possible. Furthermore, it means that a low viscosity promotes penetration of the coating material, thus accelerating underfill. The penetration volume is inversely proportional to the viscosity, i.e. with a viscosity of 100 mPas the time needed to fill a space is reduced to a tenth of the time required for 1000 mPas. This is particularly important the longer the edges of the ASICs become. When coating and where complete underfilling is desired care must be taken that the air underneath the component is given the time and opportunity to escape.

The physics of micro-casting

The complete underfilling of large components prevents the formation of microclimates in those areas and ensures the climate-proof insulation of potentials positioned there while also promoting a good thermal coupling between the components and the assembly substrate. Although the thermal conductivity of the conformal coating is not very high at approx. 0.3 W/mK, it is still 10 times higher than that of an air pocket (approx. 0.03 W/mK).

Figures 3 a and b show the coated component leads of an ASIC. There is still a clear “micro-casting” effect on the angular leads (figure 3 b) at a layer thickness on bare areas of approx. 100 µm while the solvent-based lacquers only achieve a thin film with voids under the leads (figure 3 a).

The underfilling in these images also gives an indication of the thermal expansion properties. Although, while the expansion coefficient certainly plays a role, in an overall evaluation the E modulus and adhesion power must equally be considered.

The elasticity modulus is of consequential importance when seen in combination with thermal shock loads. On a populated assembly there is an imbalance of thermal expansion coefficients (base material, copper, solder, components, etc.). In the case of thermal shock, these different thermal expansion coefficients lead to tension, i.e. different thermal movements (e.g. bimetal effects).

The following simplified equation describes the different thermal expansions and their mechanical consequences (mechanical tension between the components):

s th = mechanical tension due to temperature change

E = elasticity modulus (Young’s modulus)

µ = Poisson’s ratio (lateral contraction index)

a = coefficient of thermal expansion

dT = infinitesimal change in temperature

DT = difference in temperature

(For a better understanding the equation is restricted to two materials – Index 1 and 2.)

The elasticity modulus is a measure of the rigidity / deformation resistance of a material. The higher the E modulus the more tension must be applied to achieve a deformation. These fundamental facts are not only obligatory for casting compounds where in the worst case an incorrect rating would lead to delaminations on/of components and thus to the immediate failure of the assembly during thermal stress. With standard conformal coatings an incorrect evaluation would not usually lead directly to component failure, but “too rigid” conformal coatings would more likely crack under the applied force in the case of thermal shocks. The mechanical tension exceeds the tensile strength of the ink film which then has a greater tendency to tear due to the thinner film compared to a casting compound rather than transfer the energy to the components. In turn, the tears in the conformal coating will cause tracking currents and failures when exposed to moisture (e.g. dewing).

The “driving force” is the temperature difference. Marginal temperature differences during application (e.g. from 10 to 40 K) will only cause minor mechanical strain. However, if the assembly is subjected to temperature switches from – 40 to + 125 K, for example, the temperature difference of 165 K will generate marked mechanical forces. Experience shows that the low temperatures are more frequently responsible for problems with thermally induced stress. This can also be explained by the elasticity modulus. The elasticity modulus itself is temperature-related and increases at cold temperatures, the polymer “freezes”. A rise in the elasticity modulus is especially noticeable below the glass transition temperature.

Slight variations in the coefficients of thermal expansion equally reduce the tension induced by the temperature difference. However, it is extremely difficult to achieve a value below 20 ppm/K (equivalent to base material (FR4) or metals) for polymers which normally exhibit a coefficient of thermal expansion in the range of approx. 100 to 250 ppm/K. Under components with a large surface area, such as QFPs that are 10 mm or more in length, a further phenomenon can be observed which must be considered in the ink qualification procedure. The thermal expansion (formula 2) is usually an isotropic process. The expansion takes place in all three axis directions to the same degree. In particular in spaces tightly filled with casting compound, the thermal expansion in all three axis directions is impeded (anisotropy) and the z expansion is potentially “rerouted” into the x-y direction. The alternative would be to “burst” the space. Accordingly, particular attention should be paid to the E modulus (Young’s modulus) and the cohesion of coating material and component.

When the component impairs the z axis expansion and no “eruption” occurs, a flow model similar to that of viscous flow can be expected (figure 5). Significant expansion is only possible in two directions – in x and y direction. The expansion caused by the change in temperature can only take place at one level and it is conceivable that the polymer will expand as shown in figure 5. The directly bonded polymer is relatively immobile while the polymer in the centre of the space can move or generate tension according to its cohesive powers – the E modulus.

It can be derived from this scenario that stress transferred to the structures surrounding the polymer is not only influenced by the E modulus and expansion coefficient but also strongly depends on the adhesion of the polymer to the various structures. To look only at the expansion coefficients is an extremely simplified viewpoint which does not reflect real-life circumstances. Also with thick film lacquers it is more likely that the film will tear than for the components to be destroyed. The resultant tension from the illustrated simplified formula (2) is decisive for the stability of a system under thermal shock stress.

It becomes apparent that the three factors elasticity modulus, thermal expansion coefficient and glass transition temperature must be optimised. A key factor in reducing the mechanical stress s is the elasticity modulus which is directly proportional to the tension. In this case, it is evident that with suitable polymers it is certainly possible to reduce the mechanical tension incurred by thermal stress by 100 times. From this scenario, it can also be derived that areas with reduced cohesion induce additional tension in the coating system. When exposed to thermal shocks, especially solder paste residues have an affinity to fuse and solidify and consequently to crack and do not form a sustainable substrate due to their relatively low cohesion. The result is tension within the layer of coating material as well as vertically on the paste residues. This effect is intensified when melting processes take place under the coating.

Conclusion

Due to its dual cross-linking mechanism this lacquer system shows a considerably lower shrinkage during the cross-linking process than comparable conventional UV systems. With its process-friendly UV technology the conformal coating system Twin-Cure offers major benefits over conventional conformal coatings. It combines the advantages of a fast UV cure with the additional capability of cross-linking in shaded areas by means of a progressive reaction in an easy-to-handle 1-pack system with the resistance of a 2-pack system. Thick film applications can be realised within minimum processing times. Besides its ecological and economical process advantages, such a lacquer system also offers unbeatable efficiency in the face of potential climatic, chemical and mechanical loads. The coating thicknesses to be applied are approximately 60 µm to 120 µm dry film thickness. It can be classified a true thick film lacquer which unites the advantages of increased resistances with a process-friendly drying/cure. Twin-Cure exhibits highest performance capabilities with respect to potential climatic, chemical and mechanical loads even in the presence of no-clean flux residues on the assembly surface. Due to the multitude of fluxes available on the market, pre-trials are recommended. Since this is a solvent-free coating material, it already poses an optimum solution with respect to the VOC directive coupled with an improved protection of assemblies.

EPP Europe 417

Zusammenfassung

Elektronische Baugruppen werden immer “unfreundlicheren Umweltbedingungen” ausgesetzt. Neben rein thermischen Prozessen kommt die Kombination mit Feuchtebelastungen (z. B. Betauung) hinzu. Die Betauung ist ein Adsorptionsprozess, deren negative Einflüsse auf die elektrische Isolation durch Beschichtungen sicher vermieden werden kann. Beschrieben werden die Grundlagen zu Feuchte und Betauung, der Einfluss von Kontaminationen sowie die Besonderheiten von Dickschichtlacken bezüglich ihrer Fähigkeit, Bauelemente komplett zu umhüllen.

Les composants électroniques sont exposés à des conditions ambiantes toujours plus dures. Aux processus purement thermiques viennent s’ajouter les contraintes d’humidité (par ex. la condensation). La condensation est un processus d’adsorption dont les effets négatifs peuvent être évités efficacement par isolation électrique avec des revêtements. Ce texte décrit les principes fondamentaux d l’humidité et de la condensation, l’effet des contaminations, ainsi que les particularités des vernis à couches épaisses en matière de capacité d’enrobage total des composants.

I gruppi costruttivi elettronici sono esposti sempre più spesso a “condizioni ambientali poco favorevoli”. Ai processi puramente termici può essere associata l’esposizione all’umidità (ad es per immersione). L’immersione è un processo di assorbimento i cui effetti negativi sull’isolamento elettrico possono essere eliminati in modo sicuro con rivestimenti. Vengono descritti i principi dell’umidità e dell’immersione, l’influenza delle contaminazioni e le particolarità delle vernici a pellicola spessa in quanto a capacità di avvolgere completamente gli elementi costruttivi.

References

A. Goldschmidt, H.-J. Streitberger: BASF Handbuch Lackiertechnik, Vincenz-Verlag Hannover 2002

M. Suppa: Conformal coatings – problems and solutions, paper presented at the SMT/Hybrid/Packaging 2008 in Nuremberg

G. Habenicht: Kleben, Springer Verlag 1997

D. W. van Krevelen: Properties of polymers, their estimation and correlation with chemical structure, Elsevier Scientific Publishing Company 1976

M. Suppa: The cleanliness and coating of electronic assemblies. Climatic and tracking resistance – high-speed application of conformal coatings using UV technology, Lackwerke Peters, report No. 160 E, paper presented at the SMT/Hybrid/Packaging 2004 in Nuremberg

Share: