ERS electronic, a leading supplier in thermal management solutions for semiconductor manufacturing, upgrades its Warpage Adjustment Tool (WAT330), to include powerful capabilities for warpage measurement and correction.

Fan-out Wafer Level Packaging (FoWLP) is one of the most prominent Advanced Packaging technologies. However, wafer deformity, also called “warpage” remains a common issue. As the technology continues to be adopted by OSATs and has transitioned from research to high-volume manufacturing, understanding and handling warpage is crucial to avoid machine downtime and low yield.

“For FoWLP, one of the major challenges is warpage within the process flow. In our models and tests we observed significant impact from material behavior, layout, geometry and loading history,” says Dr. Olaf Wittler, head of the team Technology Characterization & Reliability Simulation at Fraunhofer IZM. “Therefore, solutions and strategies to control these influence factors for a low warpage are crucial to solve the challenge.”

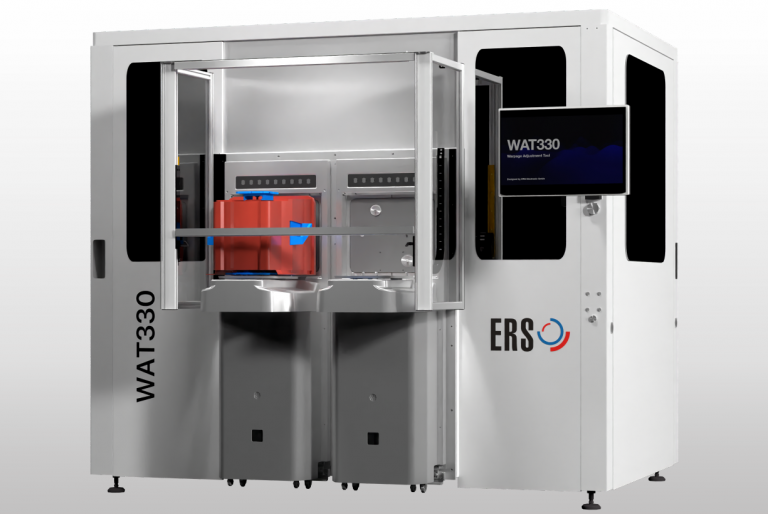

ERS has almost 15 years of experience in adjusting warpage of molded wafers in Fan-out. The company is recognized industry-wide for its patented AirCushion technology and TriTemp slide for contactless transport and warpage output of <1 mm. They can both be found in most of ERS’s machines and are typically applied for warpage correction after thermal debonding. However, with the WAT330, companies can address the issue of warpage regardless of where it occurs.

“Warpage is a top concern in high volume production and will remain so as the structure of FO becomes more complex,” says Debbie-Claire Sanchez, FO Equipment Business Unit manager at ERS electronic. “We therefore extend our warpage correction capabilities to a standalone machine, which can be deployed in-between processes to aid manufacturing.”

The upgraded WAT330 comes with a HEPA filter system for cleanroom class 100. It is also fully compliant with the GEM300 SEMI standards and compatible with automated product loading and unloading. Another noteworthy upgrade is the machine’s Nitrogen environment, which can reach down to 0.5% O2 level to avoid Cu oxidation. The new WAT330 also features strong vacuum thermal chucks for no-fail wafer handling.