Intro

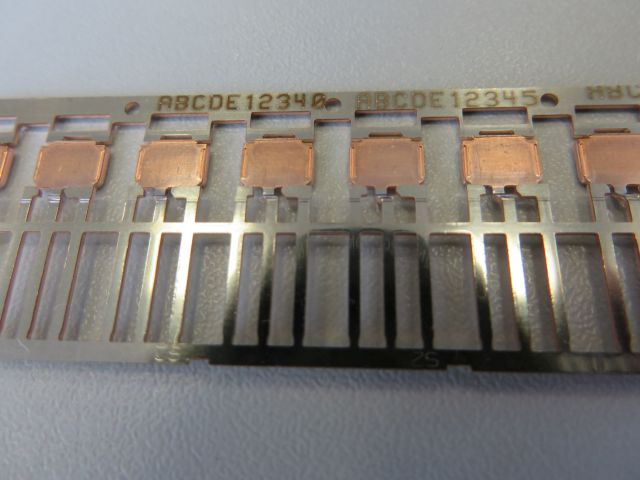

A lead frame is the metal structure inside a chip package that carries signals from the die to the outside. It is usually formed from a copper strip. It may be treated by a plated finish to prevent the copper from oxidation. Depending on the metal surface different lasers are used to form a direct laser marking to achieve a permanent marking for traceability in semiconductor packaging.

No need for consumables and the speed of processing lead to the low COO of the laser marking process.

Laser Marking Physics

Common available laser technologies start from the long wavelength IR low power CO2 lasers at 10.600 nm through NIR DPSS laser or fiber lasers at 1064 nm to DPSS lasers with SHG at 532 nm or THG at 355 nm.

Converting DPSS lasers from the fundamental NIR wavelength to VIS green or UV is often called frequency doubling or tripling.

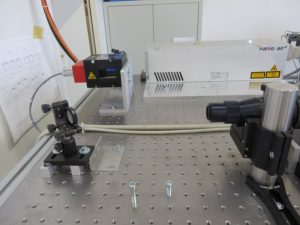

The beam steering in laser systems is common for all useful wavelengths. So-called Galvo Scanners use galvanometric beam deflection by mirrors to position the laser beam very fast and precise. Appropriate f-theta lenses and beam expanders allow for the right laser spot size and working area in XY commonly called scan field.

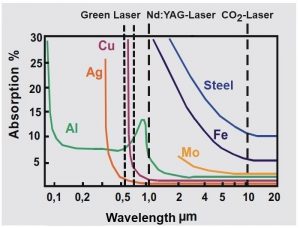

The type of laser beam sources used for marking are process specific. Lasers in IR show almost no absorption in leadframe metals and are useless therefore as almost 100 % of the laser radiation is being reflected.

Absorption of NIR laser radiation at 1064 nm is low in bare polished copper at room temperature and increases with temperature. This effect allows to use specific fiber lasers with adapted pulse lengths for marking copper.

Fiber lasers are well established in electronic industries due to their ease of integration and low maintenance and come at an attractive price. Especially MOPA fiber lasers with their wide range of laser parameters including pulse length can be used effectively for laser marking applications.

Using 532 nm green lasers for marking benefits from the higher absorption in copper. In addition, the shorter wavelength allows for smaller spot sizes.

Blue 450 nm diode lasers are recently available at attractive cost and allow for even better absorption in copper due to their shorter wavelength.

The aforementioned plating may help to create a good contrast and enhances machine readability.

These markings can be realized by the ASYS product line POLYPHOS MK, which is capable of laser marking metal and polymer surfaces.

Results

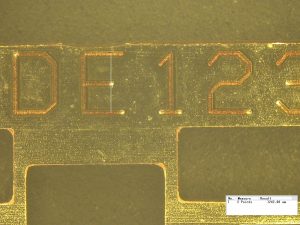

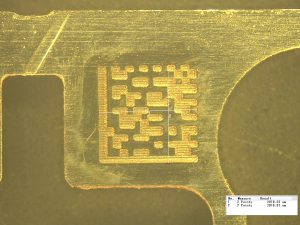

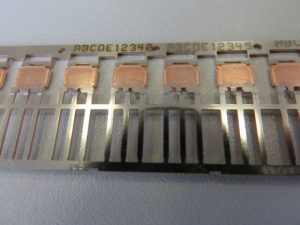

Picture 1 shows a laser mark on a tin plated TO-220 transistor leadframe by fiber laser. The following pictures are showing the results of laser marking on leadframes: