To be able to migrate from precision placement of SMD to semiconductor packaging, a knowledge transfer in several areas of the supply chain is going to take place. Christian Koenen GmbH believes that soon many SMD manufacturer will also produce components and be able to manufacture mid-size or even high quantity batches.

With this newsletter, the company will support SMD and semiconductor manufacturing with information about very efficient, high performance print processes for semiconductor packaging. In the coming months, the company will share experience specifically about the following topics:

Semiconductor backend processes

• Bumping

• Balling

• Flux printing

• Chip assembly

• Chip stack assembly

• Pre-bowed Chip assembly

• Copper Pillar chip assembly

• Chip moulding and filling

• Conventional LED assembly

• Min-LED assembly

Flux printing application process

One of the reasons for flux to be printed on the surface of PCB’s or substrates is to break off all oxides. It also cleans the contact area to allow the solder to get into a metallic connection of the contact pads. Flux printing in support of solder interconnection is needed for many assembly processes, but especially for flip chip assembly and balling processes.

Flux applications are done in different ways such as dispensing, dipping or printing.

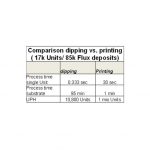

In regard to productivity and process speed, very often a dipping process takes ~1/3 of a second and a dispenser process ~ 1 sec. per dot. Alternatively, the print process takes 30 sec. but covering the whole area of the substrate in one print stroke.

In cases where more than 30 flux dots or more than 100 dice needed to be placed, flux printing is not only more economic, but also often more repeatable. If economics and process control have highest priority, then flux printing is in many cases the best choice.

At Christian Koenen GmbH, they have extensive process knowledge to design and manufacture those specialized flux printing stencils. The company is also able to test and trial those kinds of prints in their Application Lab with extensive analysis and checks to prepare and prove the individual processes for the customer. State of the art process equipment and measurement methodology is available and used to perform these prints.