Verinas verification system for PCBA cleaning was developed due to chronical deficiency of simple methods to monitor the stability of cleaning. PCB assembly has changed during the last decades due to the introduction of components with small space between the body and substrate. Cleaning under components, critical for reliability, has become a challenge.

Ionic contamination test (IPC TM650 2.3.25, 5) is not able to measure cleaned PCBA correctly because the solvent and impingement of the test fluid are not strong enough to dissolve these residues from gaps under components. Due to previous experience, first precondition for clean assembly is lack of any visible residues on the assembly. Therefore, the company, PBT Works s.r.o., has developed a Glass Test Board (GTB), which enables to visually check the residues under components.

This board consists of a glass with 400 pcs of 0805 chip models with spacing 300 μm and gap under chips 60 + – 5 μm. Chips are sealed with a patented process, which enables repeated underfilling of GTB with flux from solder paste, passing reflow oven and cleaning. Such a tool is a kind of caliper which should give the same results if the washing process has the same combination of parameters.

GTB is not built for demonstrating the maximal capability of cleaning under components; it has been designed for process stability monitoring. The proper result of cleaning (to enable the best reading accuracy) is, therefore, about 50 % of residues remaining under components on the GTB.

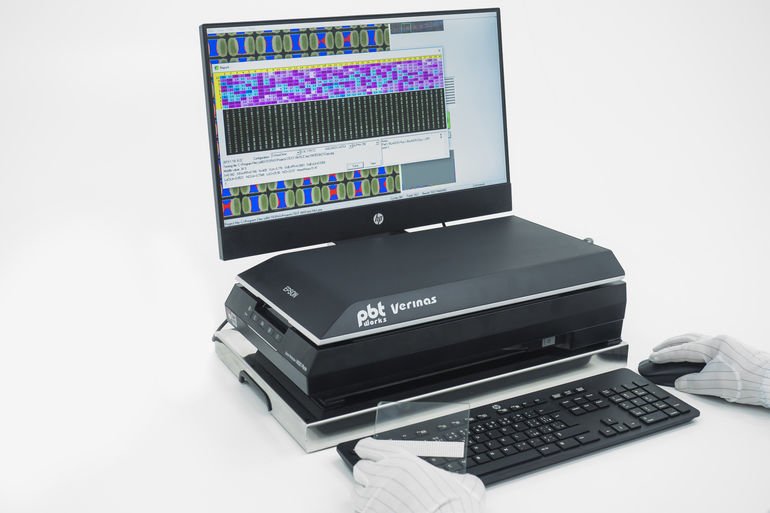

For precise evaluation, the company has developed an AOI tester, Verinas, which can detect the almost clear flux residues under components of GTB and calculate a percentage rate of flux residues under each chip of GTB separately. One test gives 400 readings, which is enough to get statistically validated data on average cleaning results. The AOI solution automatically generates a test protocol within 3 minutes.

Verinas verification can be used for:

1: comparing the solubility of different flux residues in the cleaner

For the successful cleaning process, it is essential to choose the best cleaner and flux residue combination. The AOI system offers a numerical comparison of solubility. Comparing these values enables to make an objective choice.

2: machine capability study

Currently, cleaning machine capability study is limited to measuring temperature, pressure flow, and concentration. Such measurements are time-consuming and cannot represent all influences. The combination with machine geometry will always make a process successful and stable. For the machine capability study, Verinas can be used in two steps:

- a) Process chamber uniformity check: Several GTb are placed into the chamber locations, where different cleaning conditions are expected. Cleaning of GTB and evaluating by Verinas maps the cleaning space.

- b) Uniformity in time check; Cleaning cycles run with the same set of parameters and are put to each GTB process. The differences in the cleaning results (different percentages of residues) are figures for calculating the Cpk.

3: Process capability study

With regular testing of the process of GTB, exhaustion or saturation of the cleaning chemistry is monitored due to contamination load. Repeated testing with GTB helps to determine the right interval of changing chemistry.

4: Process change validation (acc. to IPC J-STD 001 Add. 01)

GtB test effectively monitors the influence on the process after big or small process changes in the sense of IPC J- STD001 add 01.