Universal Instruments is showing that it’s more than just a successful placement machine manufacturer by highlighting in-depth resources in its surface-mount laboratory.

Equipment suppliers are increasingly being asked to offer a service that includes more than just machine sales. Customers demand access to the in-depth expertise and resources that the supplier has built up over decades in business. Universal Instruments, known for flexible placement machines and high-speed chipshooters, has recognized and reacted to this demand by devising another business strategy. “Universal has an empowerment philosophy encompassed by the phrase,” explains president Ian McEvoy. “Although we have always pursued this philosophy internally, it has perhaps not been promoted externally. We can offer many attributes and deliverables beyond the machines – for example the resources of our surface-mount laboratory – and we want to get that message over.”

McEvoy’s specific mention of this lab is not insignificant. He is keen to promote the facility which, until now, has been virtually an industry secret. The global HQ at Binghamton, USA, is home to this lab. Its staff performs three roles: researching and developing optimized processes, assisting customers in applying technology, and helps to design flexible placement equipment to meet the challenges of advanced technologies. In order to fulfill these roles, the lab has been equipped with the best in surface-mount technology and an array of analytical equipment. It is headed-up by director George Westby. In addition, Westby currently serves on the Technical Advisory Board of the Integrated Electronics Engineering Center at Binghamton University. He is also a director of the Area Array Consortium, a US-based body for the evaluation of advancements in BGA, CSP, WSP, DCA and microvia PCBs.

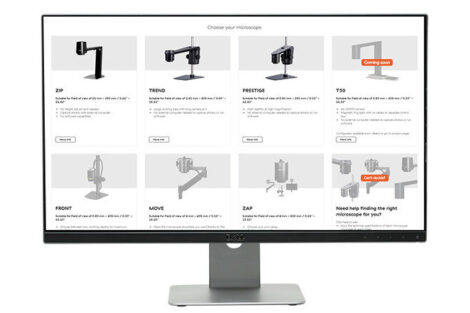

The lab isn’t simply a token attempt by a machine manufacturer to try to impress customers with a few analytical tools; it is a highly impressive enterprise. A surface-mount assembly line that wouldn’t look out of place on a medium-volume factory floor, dominates the lab. The rest is home to an array of analytical and inspection equipment that covers the spectrum from chemical and metallurgical analysis through to failure analysis of components and complete assemblies. Examples of the capabilities include scanning electron microscopy, non-destructive imaging, thermal analysis, cross-sectioning, optical inspection and materials characterization.

Universal is in a unique position among equipment manufacturers in that it can draw on a reservoir of expertise from across the assembly process to conduct the task. Printing, placement and reflow are covered by its own specialists and those of sister companies DEK and Vitronics Soltec. This dedicated group of process engineers and scientists, in addition to developing processes for customers, are also involved in alliances with industry and academic organizations, and conduct applied research.

The choice of assembly equipment reflects the depth of expertise. DEK Infinity and two 265 GSX printers, each with vision, take care of stencil printing. A GSI Lumonics 8100 inspection machine for solder deposit analysis follows these. Universal GSM platforms are used for component placement. The reflow ovens are a Vitronics Soltec 720N XPM forced-convection machine and a 1030N XPM forced-convection furnace (both nitrogen capable). In addition, the lab houses Asymtek Millennium and GPD DS-9000 underfill dispensers, and SRT Sierra 1100 rework station together with a Metcal BGA3500 rework system (complying with BGA and CSP issues).

“Our services break down into three main categories,” explains Westby. “Research and development, the transfer and implementation of technology, and process support including failure analysis. We address each of these areas with the same objective: to have a fundamental impact on our customers’ manufacturing capabilities, particularly to maximize their yield and long-term product reliability.” Westby’s responsibilities include ensuring that the lab focuses on research that is most likely to benefit the company’s customers. “We track technology through conversations with customers and industry alliances,” he states. “Then, for example, we may generate a list of potential topics and then call dozens of companies in the industry to validate the interest level. Eventually we end up with six or seven basic topics. We conduct the research in a different way to the way a university may do so. The studies are based on actual customer demands and the processes we develop through the research can be practically applied in typical electronics manufacturing environments.”

In addition to the applied research, the facilities of the lab are available for customers. For example, Universal will conduct a production process and procedure review for printing, placement, reflow and special processes (for example flip-chip and odd-form assembly), and recommend the process to improve production yield. The customer receives a report outlining the optimized process parameters. Often, however, process research engineers can assist with basic process troubleshooting without an audit. By simply understanding some of the customer’s parameters, materials and processes, they can help improve yield through suggestions based upon research conducted in the lab.

As failures are expensive and time-consuming, the company offers failure analysis that can pinpoint the specific causes. In addition, through relationships with many major component suppliers in the industry, the company can work with them to ensure that component-related failures are addressed at the design and manufacturing level of the component. Westby cites an example, “The customer was regularly experiencing a failure of the BGA on their PCBs and it was driving yield down. Through a shadow moiré analysis we were able to determine that the failure was being caused by poor design of the BGA.” It transpired that as the component went through reflow, the temperature caused it to deform significantly. Shorts at the corners of the component occurred due to packaging problems. In this case, Universal worked directly with the supplier to help redesign and requalify the device so the board assembler could increase its yield. “It was truly a win-win situation for everyone involved.”

As the company forges another approach to the supply of fully integrated assembly solutions, the lab is bound to loose its seemingly covert status. That suits both McEvoy and Westby, who believe that promoting the lab underlines the company’s commitment to leveraging its assets to help customers improve productivity. “We want to offer the total assembly solutions that Electronics Manufacturing Service providers are now demanding,” concludes McEvoy. “The relationship with DEK and Vitronic allows Universal to leverage stencil printer and reflow expertise which is applied to customer problems through the facilities of the laboratory.”

Extra: Generally, in articles marked with the Spotlight sign we provide insight and experience in an opinion-based style. Every Spotlight item therefore reflects the opinion of its author(s).

Share: