Green manufacturing is a worldwide issue now, but the transition has been put off in Europe until 2006 or 2007, respectively. As an update to our ongoing reporting on lead-free processes, we take a thoughtful look here at paste alternatives, oven technology and temperature profiling. From the process point of view, we will clarify: what is required to go lead-free? It’s of course reliability, costs and compatibility.

There are many kinds of debris generated from board assembly operations such as toxic fumes/pollutants, solder dross, contaminated wipes and fluids. Some have recycling value, and others are simply disposed of as hazardous waste. Therefore, environmental concerns are very important. Both the electronics and component manufacturers are primarily in need of solder alternatives that do not compromise product quality.

Unfortunately, there is no direct drop-in paste replacement available. The greater use of lead-free solders has led to the discovery of some of their properties. For example, high joint strength, better fatigue resistance, improved high temperature life and harder solder joints are among these features. Not all lead-frees are created equally, and each should be thoroughly investigated before implementation into production. Generally, most lead-frees melt at temperatures higher than those of tin-lead. Every replacement alloy has some deficiency in terms of cost or performance. For the sake of simplicity and pragmatism, since there are literally hundreds of Pb-free alloys, we consider only the most popular alternatives. These are, for example, tin-bis-muth (58Bi42Sn, 138°C); tin-silver-bismuth (various compo-sitions, 200 to 210°C); tin-zinc (91Sn9Zn, 199°C); tin-copper (99.3Sn0.7Cu, 229°C) and tin-silver-copper (95.5Sn3.8Ag0.7Cu, 217°C), also variants such as tin-silver-copper-antimony (Castin).

Having chosen the alloy, we have then to consider many other topics of high influence on the process. Components are a big concern, since many are not rated for the higher process temperatures that Pb-free alloys require. Moreover, at their terminations, for plating lead-tin is still being applied widely. Another consideration is that as the peak temperature increases, so too does the effect of moisture inside a component. If a component is rated as having moisture sensitivity level (MSL3) at a peak temperature of 225°C, if the peak temperature is increased to 235°C, that will increase it to MSL4. Then we have to look at solderability and wetting properties. Finally, for temperature profiling of the reflow process we have to take into account that besides traditional SMDs there is an accelerated use of advanced packages such as BGA, flip chip, CSP and other variations of device housings. With their different mass, they have impact on preheat, soak time peak temperature and the temperature variance (delta t) across the board assembly. This value should be kept as small as possible in order to gain an acceptable process window. (gbw)

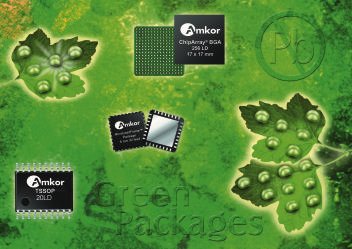

In our announcement of this editorial special on lead-free manufacturing, we promised to present the most profound trade magazine special on this subject in Europe this year. And here´s the proof: a wealth of valuable information on all relevant aspects such as paste alloys and their benefits or trade-offs, green device packages, soldering technology (please see cover story on selective methods and their impact on lead-free processing) and in the PCB & Assembly section, we also present two features partly covering rework in a lead-free environment. In addition, various update itemsare circling around on many different lead-freesubjects.

Share: