Studies regarding the climactic reliability of different lead-free solder pastes have revealed an increasing threat in ambient conditions. The application of such paste material has caused a concentration on the long-term reliability of lead-free solder joints. Here, we will highlight the questions and answers that have evolved during the paste development and manufacture, so that potential quality problems can be detected and avoided at the earliest possible moment.

Dr. Helmut Schweigart, head of application techniques, processes and technology of Zestron Europe

Defects of electronic assemblies due to electro-chemical migration in silver-based solder joints were documented as early as the 1950s. At this time, the common way of manufacturing electronics was a kind of ”bread boarding”, resulting in a ”flying” circuitry. That means tube sockets, large discrete components, connectors and terminal and pin strips were mounted in a steel frame and connected merely by wires. Therefore, width and pin pitch was usually in the order of a few centimeters, and not a problem at all. In addition, electronics of those days were not exposed to wind, weather or sharp climate changes as they are today, but were mostly used in secure rooms, and in case of professional electronics, the space was normally air-conditioned.

So, have a look at the problems that now electronics manufacturers are encountering in using lead-free paste alloys containing silver. In contrast to tin and lead, silver forms hydroxides that are readily soluble in water. These are formed as a result of electro-chemical migration and can then be diffusible in thin moisture films at a relative humidity as low as 60% (figure 1). Therefore, silver-based solders are inherently susceptible to electro-chemical migration at relative humidity levels above 60% (this is the upper moisture range of rooms that are not air-conditioned). Silver is also prone to sulphurization (reacting to sulphur compounds), which can cause short-circuits and opens, particularly in hybrid circuits. This process is extremely favorable at the above-mentioned humidity level.

Discontinuous resistance measurements

Climate resistance measurements carried out by Tabai Espec in Japan revealed the formation of dendrites with a brief life span of 10 to 15 minutes because of electro-chemical migration (figure 2). The tests were most likely conducted on non-cleaned comb structures at 85°C/85% relative humidity with a permanently applied voltage of 50VDC (maximum accelerated test conditions as established by Dr. Wege et. al. at Munich Technical University).

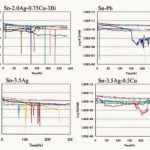

Silver-free, eutectic tin-lead solders, used for comparison, did not have such a failure pattern. Brief resistance failures have not been observed in the past because the climate tests conducted were limited to discontinuous surface resistance measurements, as defined in the corresponding standards. The phenomenon can be explained by the uniform distribution of the silver with a maximum of 4% in the soldered joint (figure 3). The electro-chemical migration mechanism activates only the silver that is close to the surface of the soldered joint. This means that only low concentrations of silver hydroxides are available. Accordingly, only filigree dendrites with a very low current-carrying capacity can be formed. These dendrites lower the surface resistance primarily in the final stage of their growth, but are then burnt off by a short-circuit effect so that the original surface resistance is re-established.

At normal (ambient) temperatures, the rate of renewed silver supply to the surface of the solder joint is slower than the attack by electrochemical migration. This is the reason why short-life bridges are repeatedly formed that have never transformed into constant short-circuits. This phenomenon results in inexplicable defect patterns in electronic assemblies that cannot be systematically repeated and not be discovered by discontinuous resistance measurements.

Continuous resistance measurement

Newly developed measuring equipment enables continuous, parallel resistance measurements of several test samples during air-conditioned storage. These continuous tests can clearly detect short-life dendrite formations. This type of measuring equipment from Tabai Espec (figure 4) was installed at Zestron Europe’s lab in Ingolstadt/Germany.

On-going research currently discussed in the Work Group for Lead-Free Joining in Electronics and on the Augsburg Technical University aims at illuminating the influence of solder-alloy formulations. The research has focused primarily on the climactic reliability of lead-free solder in respect to Cu-content and the level of its contamination. It is imaginable that a low copper content is sufficient for a shift in the corrosion potential, causing the formation of a corrosion restraining covering layer. The failure mechanism indicates that even traditional tin-lead-silver solders can be affected. Deliberations are in hand to also integrate these issues into the planned tests.

Compared to conventional tin-lead alloys, a much greater corrosion favoring effect exists with silver-based solders due to the high solubility rate of silver hydroxide in moisture films and the low critical relative humidity of 60%. In particular, carboxylic acid-based activators in solder pastes can result in a steady increase of the adsorbed moisture film. It is therefore possible that the value of the critical humidity level could drop below levels that are typically found in air-conditioned rooms. The removal of hygroscopic residues (carboxylic acid, salts) through assembly cleaning can contribute to a significant improvement of resistance to elevated humidity levels and reduce susceptibility to migration.

Summary and conclusions

The introduction of lead-free solders continues to contribute to the troubled history from the 1950s with silver-based solders, and the defects caused by electro-chemical migration. Even though solder has been developed further, the expectations and demands, particularly with regard to climate-based reliability, have grown disproportionately. Increased sensitivity towards electro-chemical migration as well as damage mechanisms that were rarely observed in the past have been the result of miniaturization and the increased use of lead-free (Cu/Ni/Au) solders. For instance, the voltage potential difference between gold and solder joint surfaces that have not been completely covered can result in the formation of corrosion notches. These notches can significantly impair the permanent mechanical strength and resistance of solder joints to temperature cycles causing material fatigue.

Higher soldering temperatures and lead-free joining techniques require correspondingly adapted cleaning processes. Whether or not cleaning is actually necessary has to be individually verified based on required quality specifications. Moreover, the susceptibility of board assemblies is not only determined by electro-chemical migration and other corrosion-induced damaging mechanisms, but also by PCB design and layout. It is recommended that electronic manufacturers review the latest climactic reliability information available for an alloy. These findings will help avoiding costly returns of failed assemblies from the field.

ZUSAMMENFASSUNG

Ab Mitte des Jahres 2006 wird in Europa praktisch keine Elektronikschaltung mehr gefertigt, die Blei enthält, so die aktuelle EU-Gesetzgebung. Die Anbieter von Bleifrei-Lotpasten haben diverse Alternativen entwickelt. Aber es geht auch darum zu klären, welche Zuverlässigkeit ist von solchen Lötstellen zu erwarten? Insbesondere bei klimatischen Einflüssen Augrund von Feuchte können elektrochemische Migration und andere Korrosionseffekte auftreten.

RESUMÉ

A partir de 2006, il n’y aura pratiquement plus aucun contact électronique qui contiendra du plomb en Europe, comme le veut la législation actuelle de l’UE. Les fabricants de pâtes à souder sans plomb ont mis au point des variantes diverses. Mais, il s’agit aussi de savoir dans quelle mesure de telles soudures sont fiables. Sous l’influence climatique due à l’humidité, il peut se produire une migration électrochimique et d’autres effets corrosifs.

SOMMARIO

Dalla metà dell’anno 2006 in Europa non verrà praticamente più prodotta alcuna unità elettronica di comando contenente piombo, così l’attuale legislazione della UE. Gli offerenti di paste senza piombo per saldare hanno già sviluppato diverse alternative. Ma qui si tratta anche di chiarire quale affidabilità sia attendibile da simili punti di saldatura? In particolare gli influssi climatici, quali ad esempio umidità, possono causare una migrazione elettromagnetica ed altri effetti di corrosione.

Share: