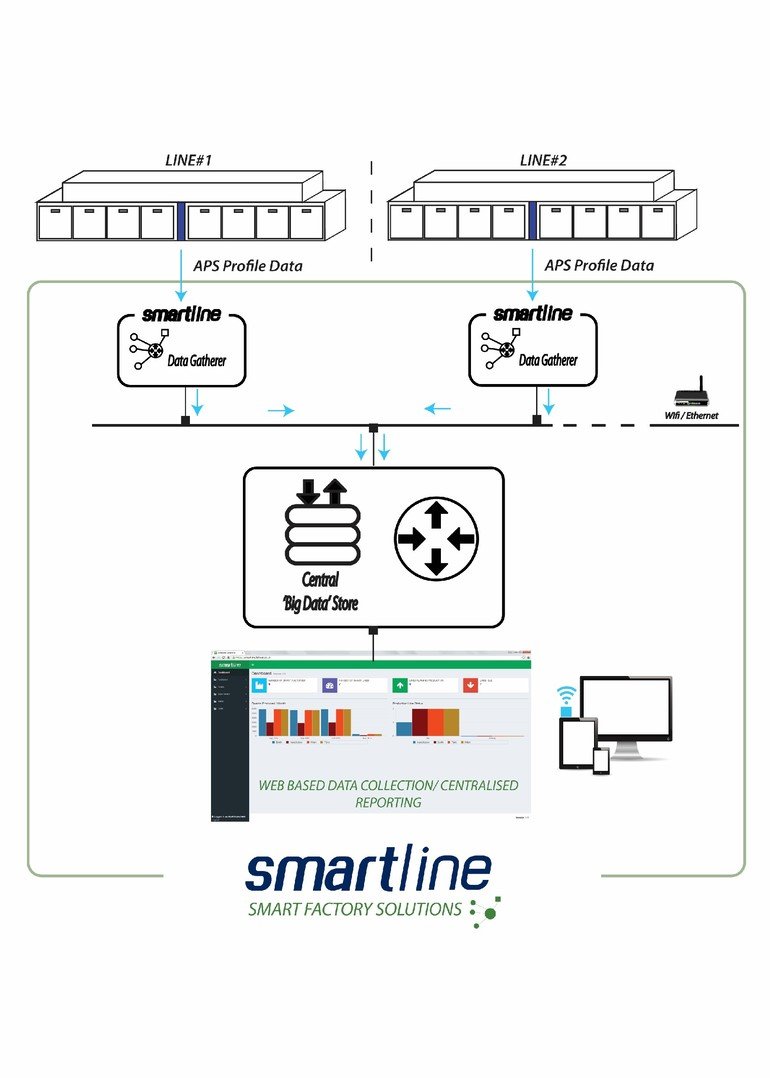

Solderstar‘s SmartLine is a state-of-the-art data capture system that builds upon the company‘s range of real-time process monitoring instruments and sensors. The new interfaces provide the network link and software for streaming of live process data from the ovens on the production floor. The system is scalable and provides all the tools today to allow ‘big data’ capture from single test/evaluations lines to full smart factories scenarios. The system was developed to work with the Industry 4.0 / Internet Of Manufacturing concept, a principle where machines are connected through intelligent networks that can control each other autonomously to create a Smart factory. Mark Stansfield, managing director at SolderStar said: “The revolution of the Industry 4.0 concept will change the face of the manufacturing process and will be very prevalent in those industries using soldering processes, for example electronics manufacturing.”

Mark Stansfield: “An Industry 4.0 factory captures information, across the whole manufacturing process so condition monitoring and fault diagnosis can be detected easily and a longer term goal of self-predicting algorithms can be used to foresee problems before they occur. This provides a company with the ability to understand and have more of an insight into its manufacturing status. This Smart manufacturing method aims to reduce down-time and has huge monetary implications in some situations.”

“Modern communication technologies and Cloud based computing is helping the Industry 4.0 revolution to become a reality. The need for increased productivity, quality and flexibility is becoming essential to stay competitive in all manufacturing sectors. The SmartLine system ensures that monitoring of the thermal processing equipment will not be left behind and can adapt to this new technological wave”, Mark Stansfield adds. The Automatic Profiling System (APS), a full time system for profiling each and every PCB soldered in a convection reflow oven, is already monitoring process conditions in real time via an array of special sensors mounted within the oven.

The system architecture uses a layered approach and is built upon existing and widely used protocols and formats. As Industry 4.0 standards develop further, it will be a simple step to integrate the data feeds into customer systems with built in support for a number of exchange formats such as XML, JSON and AMQP, with plans to embrace emerging concepts such as Open Manufacturing Language (OML).

Share: