Wave soldering systems users unintentionally throw away a lot of money in the form of good solder in dross, the layer of oxides and contaminants skimmed regularly from the surface of solder pots. But up to 70% of all dross removed is actually usable solder, mixed in with the waste. With the advent of costly lead-free solders and the required higher temperatures, the losses associated with dross will rob even more earnings from manufacturers‘ bottom line.

The solution to this issues comes, as Vitronics Soltec claims, with its dross grabber. This machine option reportedly separates good solder from real dross, and returns the usable solder to the pot, while pulverizing and isolating the waste for easy handling and recycling. Dross, the unwanted scrap in wave soldering and analogous techniques, is formed not only by metal oxides and contaminants of chemical agents, but also from non-oxidized solder. During oxidation, nuclei of solder form and are consequently enveloped by oxides. Clusters of such units form in the dross.

When the dross is manually scooped away, not only are metal oxides and contaminants removed, but also a considerable amount of usable solder. This results in the disposal and loss of a large quantity of solder. Generally it’s known that 50 to 75% of the material usually thrown away as dross is really good solder. Lead-free solders with their higher temperatures requirements will accelerate the dross-forming process, so yet higher oxidation consequently leads to even more dross. Costs or losses respectively due to throw-ing away expensive lead-free solder are thus multiplied.

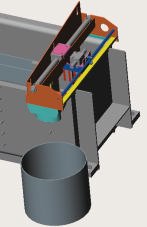

Vitronics Soltec’s standard Dross Management system directs all dross to the front of the solder pot, and prevents dross from entering the pumps and solder nozzles. As an addition to this system, the oven company has developed a mechanism that automatically cuts, reduces and removes dross from the system during operation. A grabber automatically pulverizes dross in a separate compartment, using special (user-adjustable rate) cutters that chop into the nuclei of good solder and dross, de-stroying the oxide envelope and allowing the usable solder to rejoin the reserve of solder in the pot. The remaining dross is powdered and conveniently collected for reprocessing.

Since good solder is automatically separated from the dross, the system reduces dross vol-ume by up to 70%, and that dross actually removed will be oxides and waste, not usable solder. Adjusting the tempo of the cutting system can control the fineness of the powder. The grabber also eliminates manual removal of dross from the sys-tem on a daily or even more frequent basis. This reduces overall maintenance and extends the service intervals. (gbw)

vitronics-soltec.com

Share: