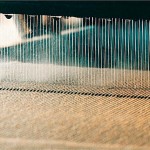

Why well-known European screen and stencil printer manufacturers use Sontara CleanMaster for automatically cleaning the underscreens and recommend this cleaning fabric to end users.

In the 1990’s, electronics manufacturing was characterized by increasing miniaturization. Components became smaller and smaller, the process cycles became faster and more efficient. And even though it was obvious that all the elements of production were being constantly improved, the level of incorrectly-produced units was not satisfactory. “It was then that we first realized that the causes for this also perhaps had to account for the cleaning roll part of the equation”, said Michael Kasper, General Manager of Vliesstoff Kasper.

“Specializing in cleaning cloths, we set ourselves to this new and difficult problem. Since at this time our company already possessed 15 years of experience in the automatic cleaning of paper-printing machines, we already had initial solutions which we could apply to the electronics industry. First, we analyzed which cleaning material had been used so far.” The evaluation of user surveys showed that a great number of products with the widest variety of cleaning rolls were used. Users couldn’t provide any precise data regarding the quality and manufacturers. The only unmistakable characteristic which all the rollers shared was the color: white.

Tests, analyses, and criteria

What quality criteria must a cleaning cloth fulfill for automatic underscreen cleaning? (Figure 1) “In the DEK company, we found a partner with whom we could discuss the existing problem and establish the desired quality criteria for cleaning fabric”, Kasper said. Within half a year, products from different manufacturers were tested. Here, two different kinds of fabric were used.

- Test group A: Cloths where individual fibers were bonded.

- Test group B: Cloths were fibers were only interwoven.

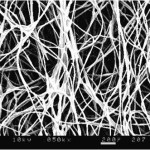

The advantage of the cloths from test group A, where the fibers were bonded, is that this procedure produced a relatively thin and thus also low-grammage and inexpensive cloth. With this production procedure, however, it is necessary to use bonding agents (figure 2), and the disadvantage is that many fibers are stuck together and thus it is not possible to have sufficient absorption of liquid and/or dirt.

“In addition, we determined that reactions between adhesives and solvents could not be ruled out. The chemical processes occurring here could not be controlled”, so Kasper. The results for the test set with the cloths that were stuck together were: They are lower-priced, thinner, but not applicable for every process and every solvent.

The goal

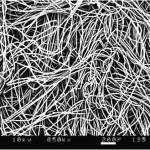

Thus, one criterion became the highest priority for them: “We wanted a cloth which the electronics industry could use with all solvents and which they could rely on for consistent quality. A cloth which didn’t rely on bonding agents so as to completely eliminate the disadvantages of the bonded cloths. So we began our test group B on cloths with fibers that were only interwoven (figure 3).”

For this test set, Kasper and his team very critically considered the fear that the fibers do not sufficiently merge in this production procedure. Since it does not result in absolute fiber mobility or extremely high suction properties, the number of the released particles had to be reduced to a minimum. According to Kasper, in this test set, it very quickly turned out that the cloths which were manufactured in accordance with the hydro-entangling method (figure 4) of the DuPont company had the best balance between suction and fiber mobility. This patented procedure is known worldwide under the name Sontara.

“This was also the time when we informed DuPont of our positive test results concerning their products,” Kasper said. “Together with DuPont, we now worked on our goal of finding the optimal cleaning cloth for automatic stencil underscreen cleaning.” They were in search of two types of cloth, those for machines without vacuum mechanisms and those for machines with vacuum mechanisms. They tested cloths with different fiber compositions and grammages. After just one year, they could present the results from their collaborative work with DEK and DuPont at the SMT 1999. The intensity with which all participants worked on the project “Optimal cleaning results for the electronics industry” also demonstrates how controversial this topic is.

“Sontara CleanMaster and Sontara CleanMaster V (for machines with vacuum mechanisms) were received very well on the market, and for nearly ten years have been the absolute mark of quality for constant and optimal cleaning in the most sensitive areas of electro-technology,” said Kasper.

“That many other cleaning fabric producers try to deceive the final customer by also calling their products ‚Cleanmaster‘ can be an indicator of our success. But only the products from the Sontara CleanMaster family registered worldwide through DuPont meet the high standards and vouch for constant quality.” As a security measure for the customer, the name Sontara CleanMaster was printed on each individual roll. In 2004 his company introduced another new development from the DuPont company at SMT: Sontara CleanMaster FP, specially designed for fine pitch stencils.

Quality standards – traceability

For quite some time, the complete documentation of the production chain has been necessary for building part manufacturing. In all companies, quality management has been taking on ever-more decisive roles. Many products in the Sontara family have also been used in the field of medical technology, and for a long time this has required a transparent production process. “For us, the foundations were created to secure another service for our customers from the electronics industry: Constant quality could be proven for the fibers up to the individual rolls – Traceability,” said Kasper. “At www.quality-certificate.com, we now give our customers the opportunity to complete their documentation with our certificate.” In just a matter of seconds and without any complications, each customer can just use the log-in information which comes with each roll and enter the roll ID number (figure 5), to print out the corresponding certificate. The roll ID number would, of course, be verified by the system for uniqueness. “This high quality standard for Sontara products has already been guaranteed for years by DuPont through traceability. We have further developed this security for the electronics industry with our service,” said Kasper.

The immediate financial advantages which customers get from using lower-priced products were often outweighed by the accompanying drawbacks (such as stop in production, increased refuse, quality risk). “The comparison tests have shown that by using the Sontara CleanMaster, production processes can be carried out with greater consistency,” said Kasper. Such a cloth was more effective at cleaning, and was thus significantly more economical than other products. Good suction power, along with the homogeneous structure of this product, made it possible to save up to 20 % in chemical solvents. This would reduce costs, was better for the environment, and was better for employees‘ health.

“Over the course of the past years, we have established that there has been a development in the awareness of how important the cleaning process is as a component within the production chain. The leading machine manufacturers have also recognized that consumables make up an important part of the positive image of their machines, for a high-quality machine can only supply high-quality results when all the products used are also high-quality. Therefore, the leading machine manufacturers recommend Sontara CleanMaster to their customers as a cleaning cloth,” said Kasper.

EPP Europe 443

zusammenfassung

Der Reinigungsprozess ist ein Baustein innerhalb der Produktionskette. Maschinenhersteller haben erkannt, dass auch Verbrauchsmaterialien einen wichtigen Anteil am positiven Image ihrer Maschinen haben. Im Beitrag werden die Vorteile eines modernen Reinigungsvlieses erläutert, das namhafte europäische Maschinenhersteller von Sieb- und Schablonendruckern in ihrer automatischen Schablonenunterseitenreinigung einsetzen – und damit auch dem Endverbraucher empfehlen.

Le nettoyage constitue un maillon de la chaîne de production. Les fabricants de machines ont reconnu que même les consommables contribuent largement à l’image positive de leurs machines. L’article décrit les avantages d’un tissu de nettoyage moderne, qui est utilisé par des fabricants européens réputés de machines de sérigraphie lors du nettoyage automatique de la face inférieure des pochoirs, et donc également recommandé aux utilisateurs finaux.

Il processo di pulitura è un elemento fondamentale all’interno della catena di produzione. I costruttori di macchine hanno riconosciuto che anche i materiali di consumo rappresentano una componente importante per l’immagine positiva delle loro macchine. Nel contributo vengono spiegati i vantaggi di un moderno panno pulitore, utilizzato da noti costruttori europei di stampanti serigrafiche e a stencil nella loro pulitura del lato inferiore degli stencil, e quindi da essi consigliato anche all’utilizzatore finale.

Share: