Once again, Semicon Europa is soon opening its doors on the Munich showground. Exhibition time will be April 1 to 3, and the programs run from March 31 to April 4. This exhibition, dedicated to all facets of semiconductor manufacturing technologies, manufacturing equipment and materials, happens in the middle of what – well – call it „consolidation“. It is widely expected that business will recover this year and return to growth. There are indeed some signs of semiconductor recovery in Europe and worldwide, and especially the encouraging situation in mainland China with its huge demand has now become the business mantra.

As it always was during this event, a full program of seminars of all kinds will be provided during the Semicon Europa. For a complete overview, our readership is kindly asked to contact Semi directly at their web site (address at the end of this article). Here we will just have a short look at some of the highlights and trends. One focus lies on MEMS (micro electro mechanical systems), for which an industry forum takes place. It provides exhibitors an opportunity to show their competence and solutions to interested visitors. The MEMS scenario is shortly characterized by a huge variety of different products, technologies and materials. Typical products are sensors of all kinds, radio-frequency MEMS or tiny mechanical silicon parts. They are applied in virtually all application areas, for example, in vehicles, micro-optics, telecom and IT equipment, and medical/biological solutions. The production is somewhat similar to semiconductor etching, but needs more modular designed and standardized MEMS devices, in order to lower manufacturing costs. During the event, the third international MEMS/MST conference will take place in Munich, and there is also a MEMS pavilion in Hall A2 on the exhibition floors.

Another large field of ongoing developments is packaging, where practically all innovative progress tends to advanced technology such as WLP (wafer-level packaging, flip chip, BGA (ball-grid array), CSP (chip-sized packages) and many more which build on these methods, for example, stacked CSP, wafer-level CSPs, etc. ”We have here an overabundance of varieties that doesn’t provide for cost-efficiency”, explains CEO Franz Richter of Suss Microtec. He sees an intense necessity for standardization in order to provide advanced packages for the volume markets in low-cost versions. Right now, too many different types of packages and processes aren’t helpful for the whole semiconductor community to get the costs down. In the future, some of the process steps in frontend and backend of semiconductor manufacture will have to join. One topical example for this trend is wafer bumping. This packaging process, traditionally a backend task, moves to the end of the wafer processes in the frontend area. Semi/Prismark market research says that the number of bumped wafers will grow from 2001 up to 2006 by a factor of 7 to a total of 23m wafers. Solutions for the backend processes (assembly, packaging and test) will be on showcase in the halls A1/A2.

Facility automation is a further outstanding subject, presented in a pavilion in hall A2. The three main segments of semiconductor manufacture are on display – equipment, facility management and information technology. A joint demonstration of processes and solutions encompasses all relevant subjects of a real factory: wet-bench, process-gas, chemicals and purified water handling, safety and control systems as well as alarm systems, factory networks and control-room equipment. The focus is on clean-room operation and the auxiliary systems, and how to automate work procedures efficiently.

As with many other industries in these dire days, this commerce is also in a deep slump. Practically all large semiconductor manufacturers worldwide have reduced their capital spending in favor of new wafer fabs, and in turn for new equipment. At the moment, today ´s available production resources are satisfactory to fulfill the market´s demands. During the last quarter of the year 2002, about ten fabs were closed worldwide, most of them running 100, 125 or 150mm lines, and built in the 70s/80s of the last century. Obviously, there is no 300mm hype to see this year (and there was none in the past), but a thoughtful improvement of production capacity by about 20 more wafer fabs exists, whereas 200mm technology still counts for the lion’s share. However, for the year 2004 there is a prognosis that 300mm lines will then make for about 60% (12 installations) of the overall newly erected fabs (150mm 3 fabs; 200mm 6 fabs).

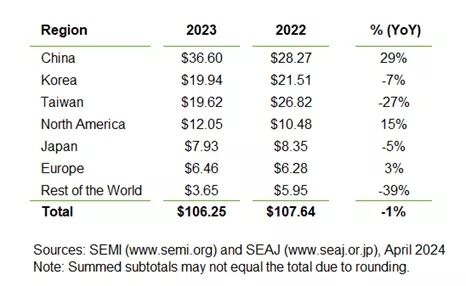

According to latest information, the actual sales of semiconductors in the year 2002 were $140.7bn, a slight growth of 1.26% from 138.9bn in 2001. For this year, according to the entire group of market research firms, the prognosis lies between a plus of 12 to 26%, and that’s a lot of variance. Too huge a gap to bridge it easily on all sides involved, be they material, equipment and semiconductor manufacturers. Therefore, all business partners have to be prepared for the unexpected, unfortunately in all possible directions.

In the year 2002, as Semi’s European director Walter Roessger pointed out, the worldwide material consumption has, with $23bn, surpassed the equipment sales with its 22.7bn. We can expect that equipment sales will be generally flat this year, except in some areas for machines enabling advanced-packaging technologies and some other facilitating methods. As long as there is overcapacity and strong price pressure (a situation where semiconductor manufacturers will barely make profits), there is no hot machine-ordering activity to notice.

Otto Kosgalwies, European VP sales and marketing of STMicroelectronics, conservatively expects only a plus of 11% for this year’s semiconductor market, which is a year of transition for him: steepest recovery from the deepest slump ever. The market pie by region is divided into four segments: Europe 19%, Japan 21%, North America 23%, Asia/Pacific with China 37%. By product families, the market volume is splitted into these main solid-state supplies: discretes, standard and opto-electronics with 22%, memories 18%, processors/DSPs 17%, and differentiated ICs with 43%. According to him, flash memories are increasing, differentiated ICs and power management; decreasing are DRAMs and microprocessors.

For larger capital expenditure, he sees a fresh beginning again in the year 2004 in the developed countries, but the Asian market expansion has continued in the past two years and will proceed with a higher rate than in the nearly saturated markets. However, the costs of manufacturing have increased very much elsewhere in the world. Typical labor cost is now only a small fraction of the entire cost complex. For example, at the beginning of the 90s, a fab could be erected with an investment of about $500m; today $3bn is the coinage for this game. Obviously, one erroneous decision and a company could be almost dead (chapter 11 in the U.S.) or in the red for a very long time. Industry in developed countries can expect an encounter with some new competitors from the Asian region, acting unconventionally (and sometimes even improperly?). But their advantage is a „hungry“ business mood and the time of new departures, not the cheaper labor. This isn’t an issue in a highly automated wafer fab. So what can we perhaps expect in semiconductor manufacturing? Besides of the 248 deals in acquisitions and mergers in the last seven years, much more of these will probably have to come.

Gerhard B. Wolski

Share: